With the MATIC and CLASSIC series, the Swiss company Tool-Temp AG is modernizing its existing range of temperature control units in terms of function and design. With the market launch of the new MATIC appliance line, Tool-Temp AG, based in Sulgen, is responding to Industry 4.0, which means that there are "almost" no limits to temperature control. The CLASSIC series, the proven classic in a new guise, is characterized by its durability and is the ideal solution when the temperature control unit's range of tasks is limited to its core function of controlling the circulating medium.

The new temperature control units in the MATIC series meet all the requirements of automated production environments. The entire MATIC product line is equipped with the new IRIS controller developed by Tool-Temp and is modularly expandable. The IRIS controller offers the entire spectrum of connectivity, from classic digital and analog interfaces to all common serial and fieldbus interfaces and the latest industrial network protocols (Profinet, EtherNet/IP).

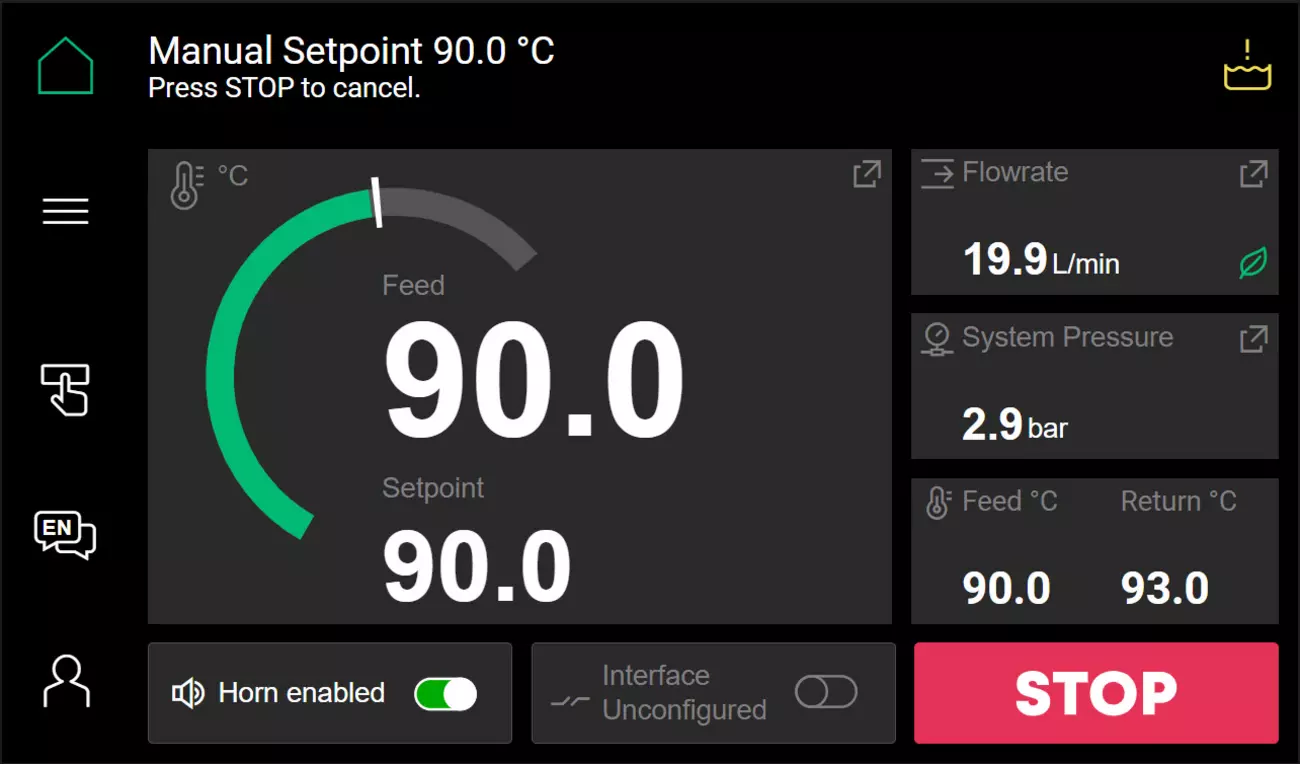

The easy-to-use touchscreen display

The easy-to-use touchscreen display

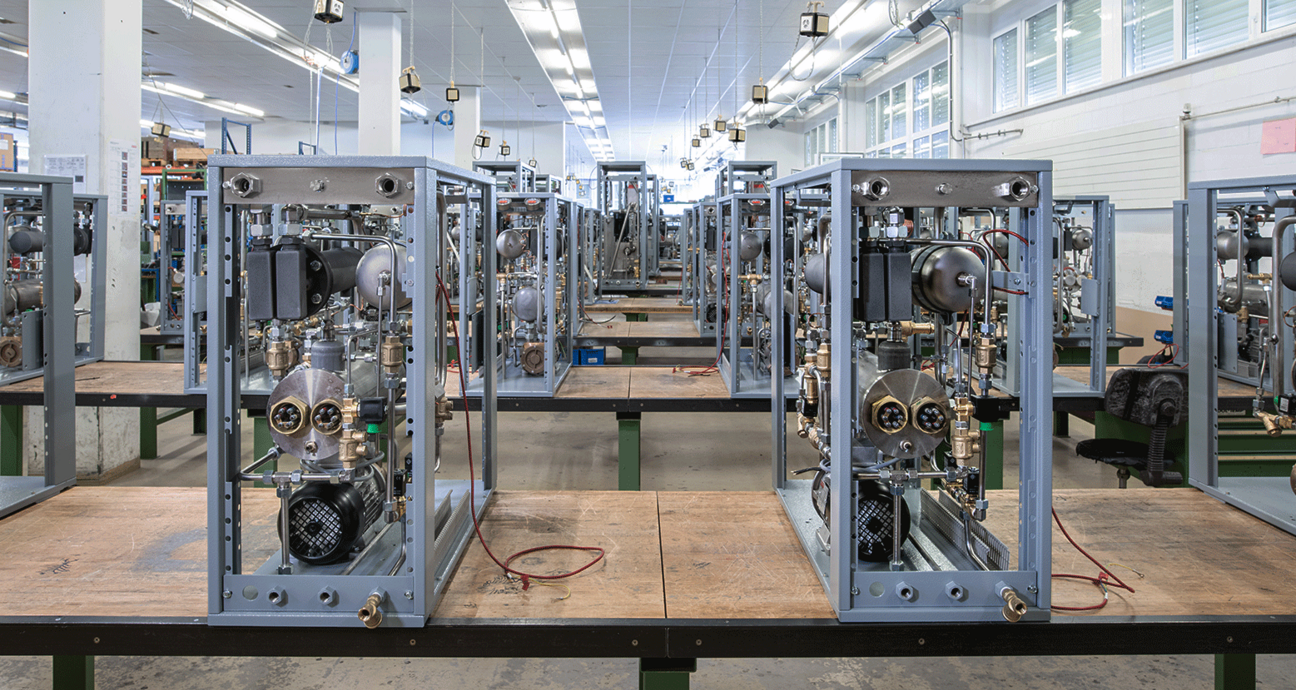

Temperature control units from the MATIC series

Temperature control units from the MATIC series