Lamination, printing & textile

Powerful temperature control devices in use

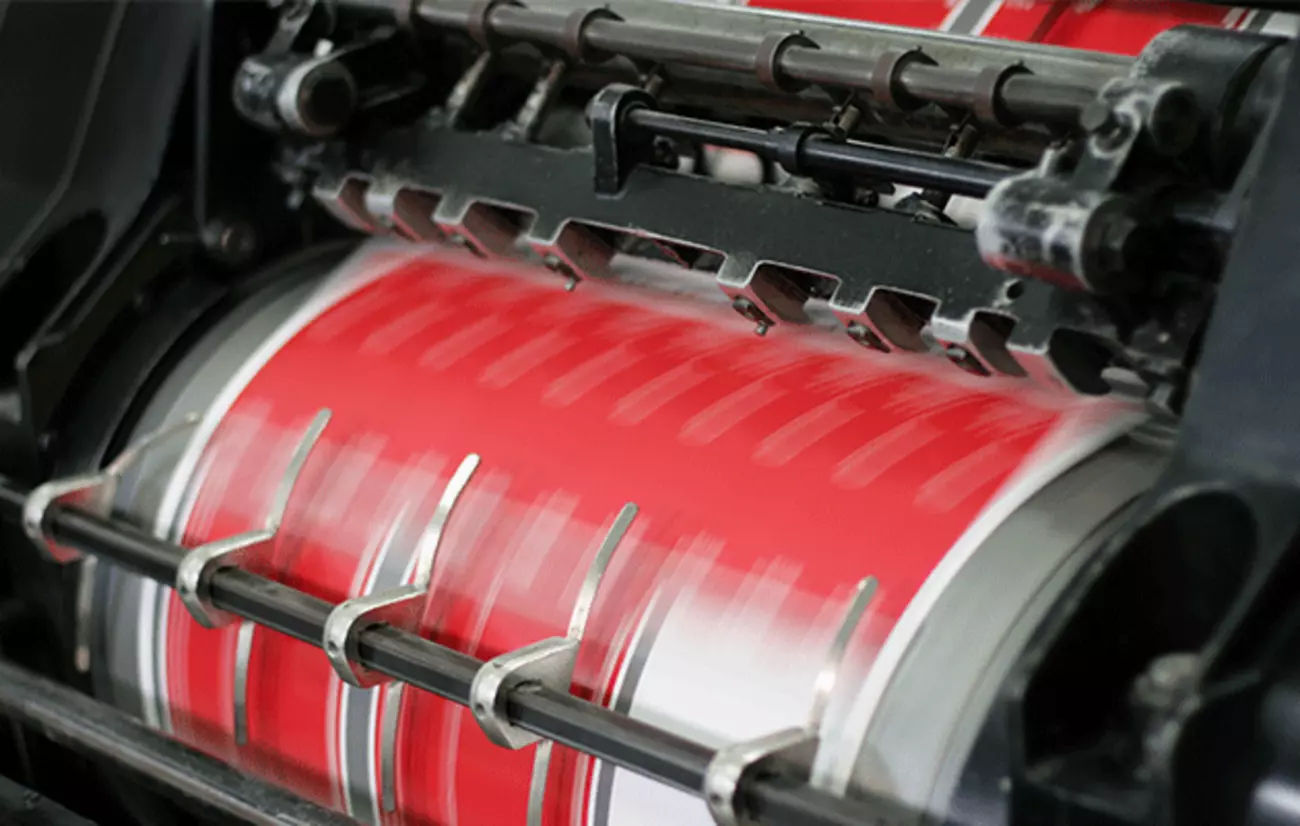

Hollow or double-walled rollers are used in the printing industry and in lamination as a finishing process. In order for you to achieve first-class results with these processes, you need perfectly handled temperature control processes - i.e. powerful and failure-free temperature control devices. In this industry, constant temperature control is crucial for success.

In the textile industry, fabric webs are connected to other materials using a roller application. Depending on the application, textiles are provided with functional layers. Depending on their function, different application methods are used. The temperature regulation of these processes is essential so that the desired function of the textile laminate is achieved through gluing or fusing.

Calender rolls, double-walled rolls, hollow rolls

The requirements for temperature control are as varied as the materials used.

Calender rolls and rollers are used in the production of foils made of plastic, rubber and metal as well as in embossing, smoothing, compacting and satinizing paper or textiles. The construction and designs of the rollers and calenders are perfectly tailored to the materials to be processed. Temperature regulation is therefore also very individual and the choice of the right temperature control or cooling device requires an appropriate calculation.

Our specialists know the special features of the different roller designs and will be happy to advise you on evaluating the right system.

Printing, lamination & textile: In a nutshell

Calenders are a system of several heated and polished rollers made of chilled cast iron or steel arranged one on top of the other, through whose gaps a material is fed. They are used to produce foils made of plastics (PVC, PE, PS etc.), rubber and metals (aluminum, tin). For plastics, comparatively thick films are produced using the calendering technique. These then come e.g. B. used in the pharmaceutical industry for blisters (blister packaging). Thin films made of PE (garbage bags) are used, for example. B. produced using blown film extrusion for time and cost reasons. Rubber films are manufactured in the range from 0.1 to 0.8 mm. These films are also doubled in the calender.

Calenders are also used for embossing, smoothing, condensing and satinizing paper and textiles. Furthermore, nonwovens made from thermoplastic polymers can be solidified into nonwovens. In the textile industry, calenders or assemblies made up of several calenders are used in a variety of ways, including as a preliminary stage for smoothing surfaces, to squeeze off excess liquor during hot fixing or to evaporate liquor residue. Various effects can also be achieved by changing pressure, temperature and roller speed.

The special thing about the temperature control of rolls is that the products produced on them are very different and the design of the calenders and rolls therefore varies greatly.

For us as a manufacturer of temperature control and cooling devices, it is therefore important to calculate and redesign every application. In addition to the required temperature on the roller and its heating times, the roller design must be taken into account. The permitted pressures on the rotary guides and the return volume must also be taken into account equally in the design considerations.

In addition, the quantity and properties of the material to be processed define the required heating and cooling output.

Many components play a role in choosing the right temperature control system. For calenders and rolls, the design of the application is very important. But the material to be processed with its specific properties and the material throughput are also crucial for choosing the right temperature control system.

We would be happy to advise you and discuss the ideal heating and cooling solution with you. Our broad portfolio ranges from:

- Water temperature control devices / 90°C max. temperature / 9 – 96 kW heating output

- Pressurized water temperature control units / 160°C max. temperature / 9 – 48 kW heating output

- Oil temperature control devices / 360°C max. temperature / 8 – 144 kW heating output

Manufacturing high-quality coffee mugs

This complex production system is equipped with an upstream extruder. In this, the starting material polystyrene (PS) is melted and then passed through a calender with four rollers. The plastic melt with an initial temperature of 230°C flows over the four rollers and is smoothed and compacted. The aim is to cool the plastic melt down to a target temperature of 120°C. When the production process starts, the rollers are heated to the desired temperature for the first time. During the continuous process, the heat from the plastic must be dissipated. After the comparatively thick continuous film has passed over the calender rolls, the material is shaped using a deep-drawing tool. The deep-drawing tool is also tempered. The tool temperature is set to 40°C to remove the residual heat from the plastic film. The final end product, high-quality coffee mugs, is produced using the deep-drawing mold.

Solution approach tool temp

Two pressurized water devices of the type TT-137 N were each connected to a roller and set to a temperature of 60°C. With a material throughput of 580 kg/hour. It is the task of the devices to cool the process. In order to meet the large cooling requirements at comparatively low temperatures of 40°C, respectively. To cover 60°C, we deliberately chose a device with integrated direct cooling.

Another challenge was the relatively large return volume, which could flow back into the devices when the process was switched off. Open temperature control systems up to 90°C could therefore not be used. The pressure resistance of the roller bushings was ultimately the final problem. In order to prevent the TT-137 N from entering the pressure-superimposed state, the maximum temperature in the controller and the safety thermostats was limited to +80°C. This meant that only the effective pump pressure had an effect on the system and the rotary guides were safe from excessive pressure.

This modification means that pressurized water devices can also be successfully used in roller applications.

The devices have been in use for several years now and work perfectly. The customer is very satisfied with this solution.

Manufacturers of plastic packaging films use pioneering and environmentally friendly materials made from biodegradable thermoplastic PLA for the packaging of food such as beverage bottles, films for vegetables, etc. This high-tech material can be broken down by microorganisms, which helps to improve the carbon footprint.

During the manufacturing process, a highly transparent, technical plastic is placed on a calender, which consists of two temperature-controlled rollers. The initial temperature of the film is approx. 300°C and is stretched over the rollers, compressed and cooled down to a target temperature of approx. 70°C. When designing the device, particular attention had to be paid to sufficient return volume. The roller should be able to heat up to an operating temperature of 70°C within one hour. The customer specified one device for both rollers. For this application a TT-118 K was supplied for both rollers. The two rollers are connected in parallel to the TT-118 K. The advantage of this connection method is that the same temperature can be achieved for both rollers. For it to function properly, sufficient circulation had to be ensured.

The customer uses various models from us in their production and appreciates their robust design, easy operation and the possibility of simple maintenance and service work.

Contact now

How can we help you?