2’200 companies from 56 countries presented their products and innovations in the Düsseldorf exhibition halls from 12 to 16 June. 63’300 trade visitors from all over the world attended the world’s most important trade fair for foundry technology. Tool-Temp AG took the opportunity to present its new MATIC line of temperature control equipment, which covers all the requirements of a production environment with digital networking. A large number of visitors were interested in this innovation, as optimal temperature control and uniform temperature distribution during the entire process are crucial in die casting.

Experience in delivering the perfect temperature

We keep your industry at the right temperature! Since 1973, we have specialized in producing temperature control and cooling units tailored for the manufacturing sector. Whether you work with plastics, in metal casting, in the rubber industry, in printing or laminating, in the chemical and pharma industries, or even in the food sector: We ensure you have the optimal temperature – we offer more than 60 standard models and numerous customized solutions to meet your specific requirements. Our extensive portfolio includes temperature control units, process thermostats and cooling units / chillers.

0

Established

0

Branches

0

Distributors

0

Employees

That's why Tool-Temp!

We are experienced

We have been producing temperature control and cooling units for the manufacturing industry since 1973. From plastics processing to metal die-casting and food production, we offer customised solutions for your temperature control and cooling processes - tailored precisely to your needs.

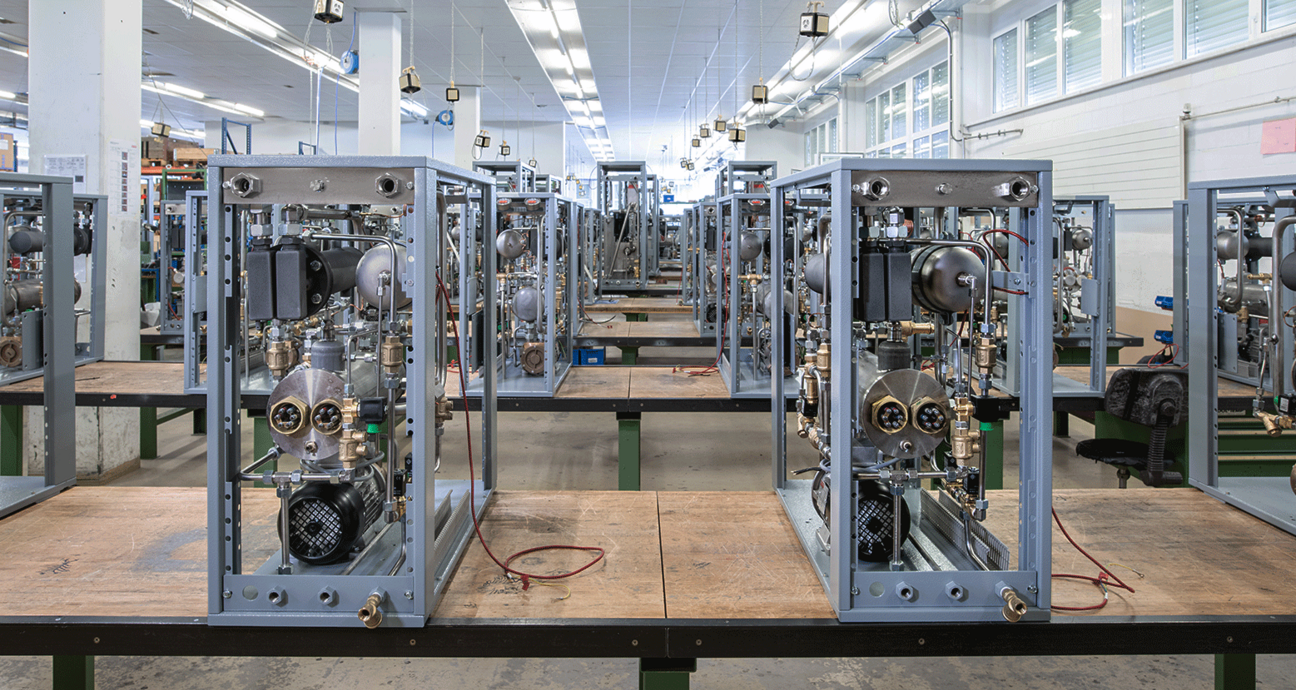

We are Swiss quality

As a second-generation family business, Tool-Temp produces all its equipment in Sulgen, Switzerland. The in-house production of key components enables the manufacture of low-maintenance and service-friendly devices for high-precision temperature control. Our approach to user-friendliness and ease of use contributes to long-term cost efficiency and optimisation of your operations.

We are innovative

The MATIC product line and the IRIS control system from Tool-Temp offer an innovative solution for process temperature control. IRIS enables connectivity, easy handling and future-orientated communication. Tool-Temp continuously develops and optimises for you.

We are global

Thanks to our worldwide network of 16 branches and numerous agencies, we are available to you anytime and anywhere. Our fast repair and spare parts service and well-equipped equipment warehouses ensure that we can help you at any time - regardless of your location.

Customised to your industry

Tool-Temp AG mould tempering attracts interest at GIFA 2023

In addition to the precise temperature control, the Tool-Temp AG temperature control units will impress their future owners with other advantages such as the long-life magnetically coupled pump developed in-house, the precise temperature measurement at the mould and the clear digital flow measurement and pressure display on the unit. The robust industrial design, which can easily withstand the harsh everyday conditions of die casting, also guarantees the customer a long service life.

At the Tool-Temp stand, visitors were able to see for themselves the capabilities of the temperature control units and take a close look at the exhibits. Jasmine Koller, Managing Director of Tool-Temp AG, explains: “We are very satisfied with the outcome of the event as well as the positive customer feedback and the high number of visitors to the stand confirms the lively interest in complete temperature control solutions in the foundry industry. Our temperature control unit portfolio was very well received by the trade visitors. Especially the new MATIC temperature control unit line with the new IRIS controller was of great interest.”

During the five days of the show, very good new contacts were made and existing customer relationships were cultivated. “We are grateful for the many valuable discussions and the lively exchange of experiences. The extremely positive response from visitors exceeded our expectations and encourages us to continue investing in our smart and intelligent temperature control solutions for production plants, which are perfectly tailored to our customers’ requirements,” concludes Jasmine Koller.