MATIC product line

The MATIC range of temperature control units covers all the needs of production environments leveraging industrial networks. The entire MATIC product range is equipped with the new and in-house developed IRIS controller, offering a broad range of connectivity features. It covers the time-tested serial and digital/analogue interfaces, classical fieldbus protocols, as well as current state-of-the-art industrial ethernet (Profinet, EtherNet/IP).

The MATIC temperature control units put your economic goals into practice. The energy-saving eco mode leverages the latest-generation variable-frequency drive installed in every MATIC unit. More intelligent look-ahead temperature control prevents unnecessary energy expenses for heating and cooling. All the while our proven immersed heaters offer a 100% conversion efficiency. In short, MATIC brings the energy consumption of your temperature control process, as well as downtimes, to a minimum.

The main features of the MATIC temperature control units

- Simple operation

- Modular easily expandable

- Predefined actions and easily configurable recipes

- Anticipatory Behavior & Predictive Maintenance

- Connectivity

- Energy efficient and ecological

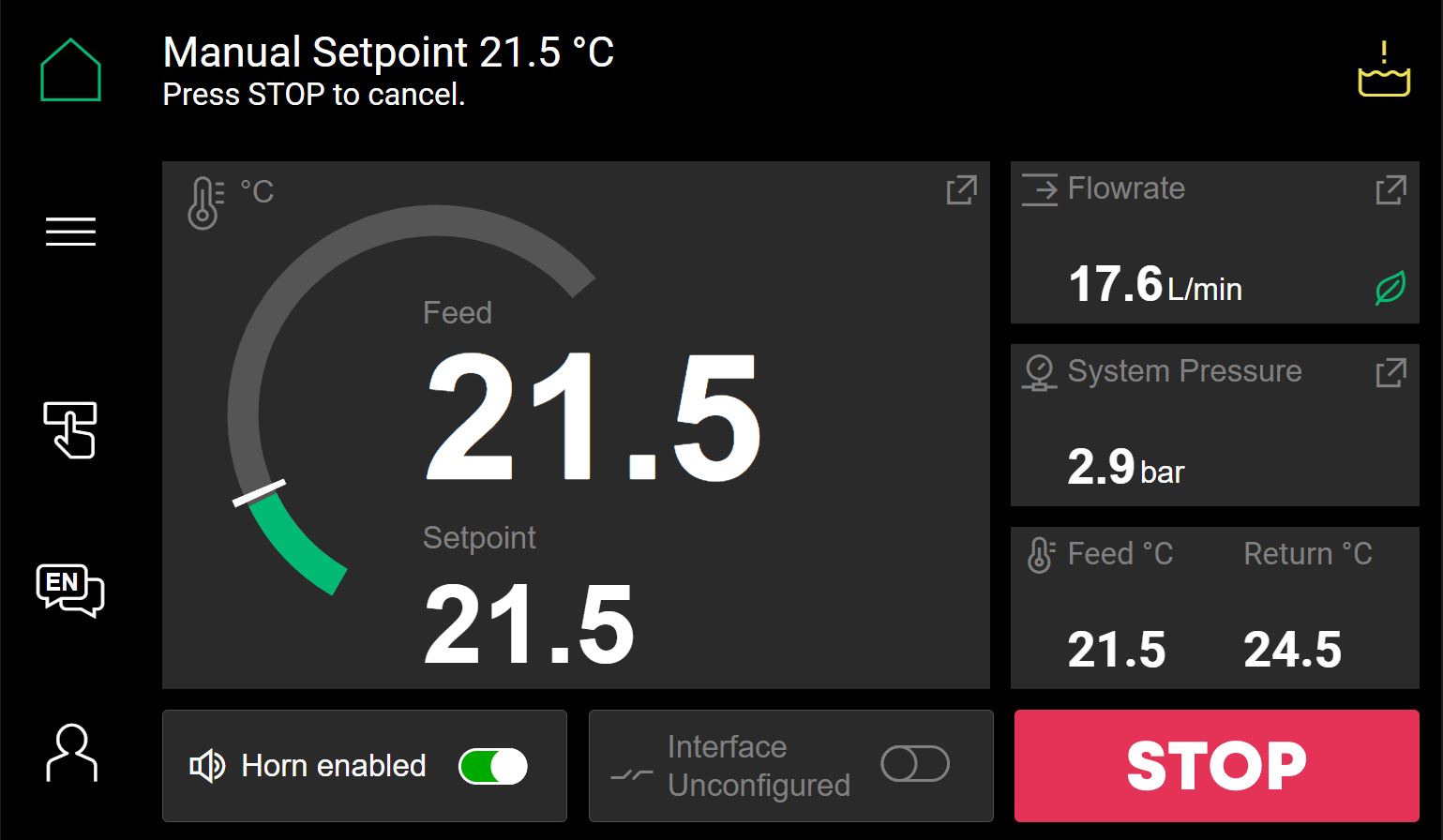

Simple operation – with high user comfort

The new MATIC temperature control units and the IRIS controller integrated in them can be operated in a very short time. A great emphasis during the development was placed on the intuitive operation of the controller. The clear and high-contrast display on the 7″ display ensures that the controller can be operated very comfortably even in difficult lighting conditions. The user interface was designed for easy and clear readability – even at a certain distance from a few meters.

Modular easily expandable – even in the field – even in the future

Input-output modules connected via a fast CAN bus serve as the central “internal” nervous system to which the sensors and actuators are connected. Thus, the controller can be adapted to the complexity of the device by using different or several of these modules. Communication with the outside world is also modularly expandable. Various communication modules can be connected to a second CAN bus – also in the field and by the customer.

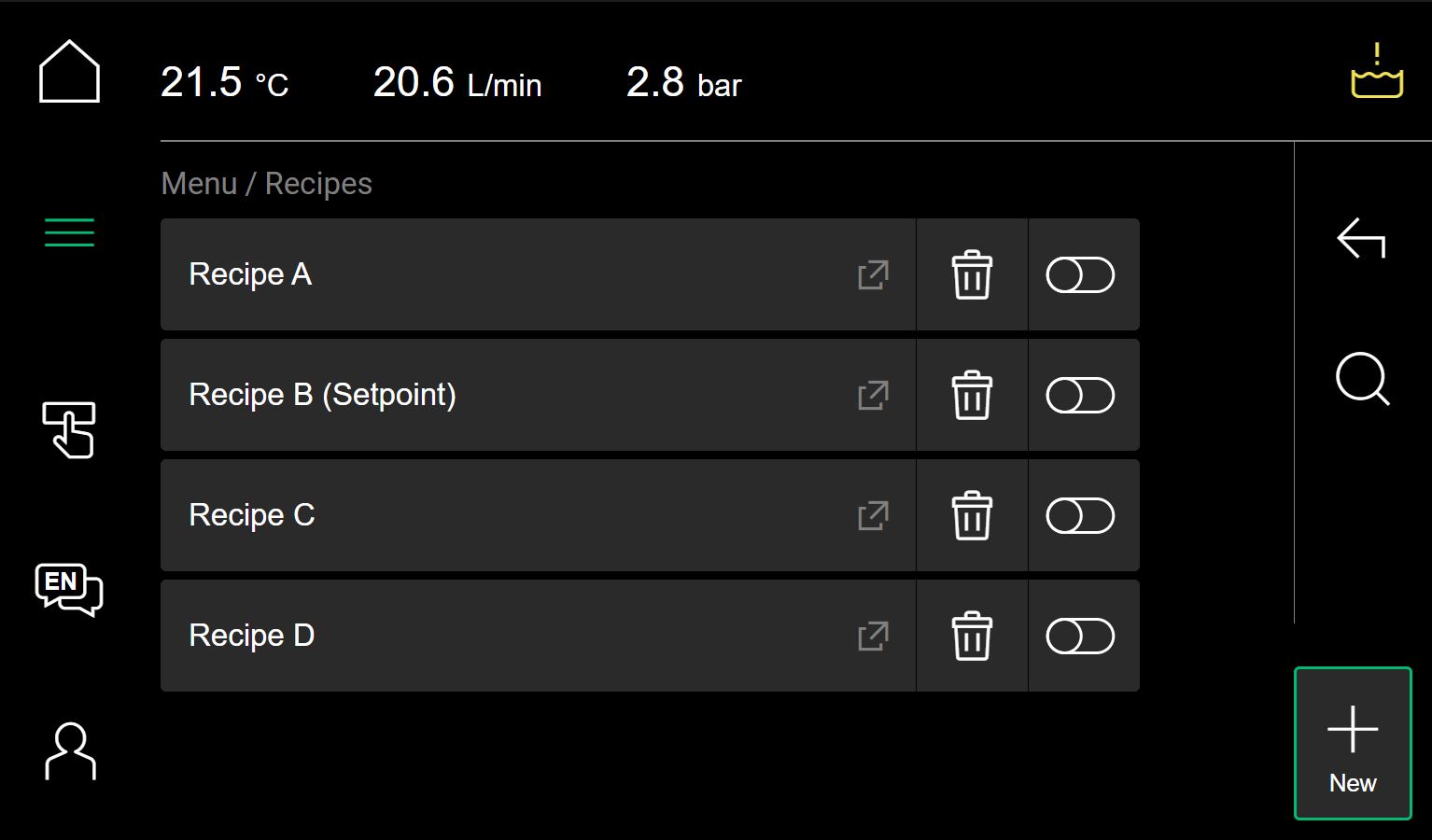

Predefined actions – configurable recipes

Fully automated partial steps and entire production recipes can be stored and saved. The desired behavior of the MATIC temperature control unit can be easily set. Thanks to flexibly configurable recipes, relevant production parameters for the desired production process can be stored and thus individual processes can be controlled and regulated. All work steps, such as tool change, are carried out fully automatically by the unit. It is no longer necessary to perform several consecutive steps manually; a single click is enough. This significantly saves working time and at the same time increases work and process safety.

Anticipatory Behavior & Predictive Maintenance

The new control system is a central and digital intelligence, which already has process knowledge based on models. In the work process, it compares the various sensor information with this knowledge and can thus react to changes at an early stage and prevent limit values from being exceeded in advance. The monitoring behaves intelligently. The behavior is constantly checked for plausibility and possible problems can be clearly identified and localized. The whole system works predictively and informs the user proactively

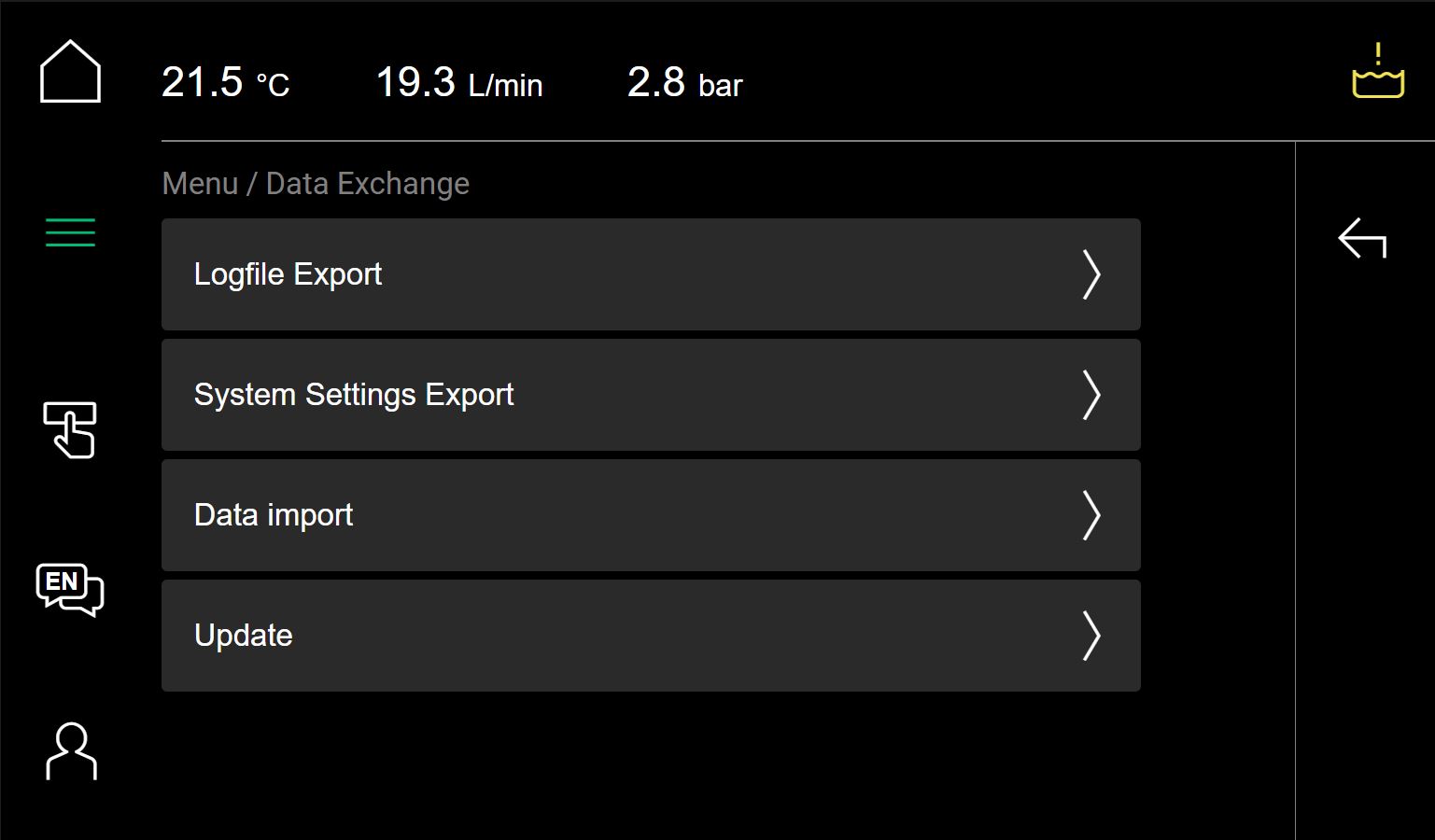

Connectivity – OPC-UA – further upgradeable for the future

Thanks to the new controller, the user can interact easily and flexibly at all levels of data exchange at the same time. In addition to local operation on the touchscreen, remote access is possible. Using a terminal device such as a phone, tablet or PC, the user can access the user interface via web browser, LAN cable or WiFi integrated in the controller. OPC-UA available by default on the IRIS controller. Add-on modules can be used to further expand connectivity as desired.

Energy efficient and economical – focus on energy saving

Thanks to the model-based control, the temperature control unit can be operated very energy-efficiently. The controller reacts at an early stage to deviations in the control variables and thus prevents temperature fluctuations completely without “counter-cooling”. Furthermore, the units of the new MATIC line are all equipped with a variable speed pump control and with a 24V DC control. The controller draws only as much pump power as it needs for the process and optimizes the energy consumption of the device at this point as well. The availability of all sensor information makes it possible to coordinate the control of flow and temperatures. The flow is controlled by a frequency converter, which adjusts the pump speed. In addition to energy savings, this makes it possible to limit the upstream pressure. The devices thus offer high energy efficiency and thus enable cost savings in use. The controller works hand in hand with the new frequency converter. The pump power is continuously adjustable and the device has an automatic eco mode. Thanks to the frequency converter, the pump thus automatically saves energy when the full pump capacity does not bring any advantage. This energy-efficient behavior enables the customer to handle resources in an ecological way.

The MATIC line of devices is divided into the following product groups

- MATIC Duo

Water up to 90°C

Oil up to 150°C - MATIC Water

Water up to 90°C

Pressurized water up to 160°C - MATIC Oil

Oil up to 360°C

About Tool-Temp

For over 50 years Tool-Temp has been developing and manufacturing temperature control and cooling equipment in Switzerland for all manufacturing industries as an owner-managed company.

Tool-Temp, as one of the leading manufacturers of temperature control and cooling equipment, is represented on all continents worldwide and has its own presence with 16 Tool-Temp companies. Tool-Temp products are used in all processing industries: plastics, die casting, injection molding, extrusion, rubber, silicone, chemical, pharmaceutical, food, printing, lamination, textile and wood.