- |

- Ligne de produits MATIC

- |

- IRIS Controller

IRIS controller for MATIC product line

With the new IRIS controller, Tool-Temp offers a smart and intelligent solution for all types of process temperature control. The user can expect ease of use and, at the same time, a state-of-the-art communication and interface solution geared to the future.

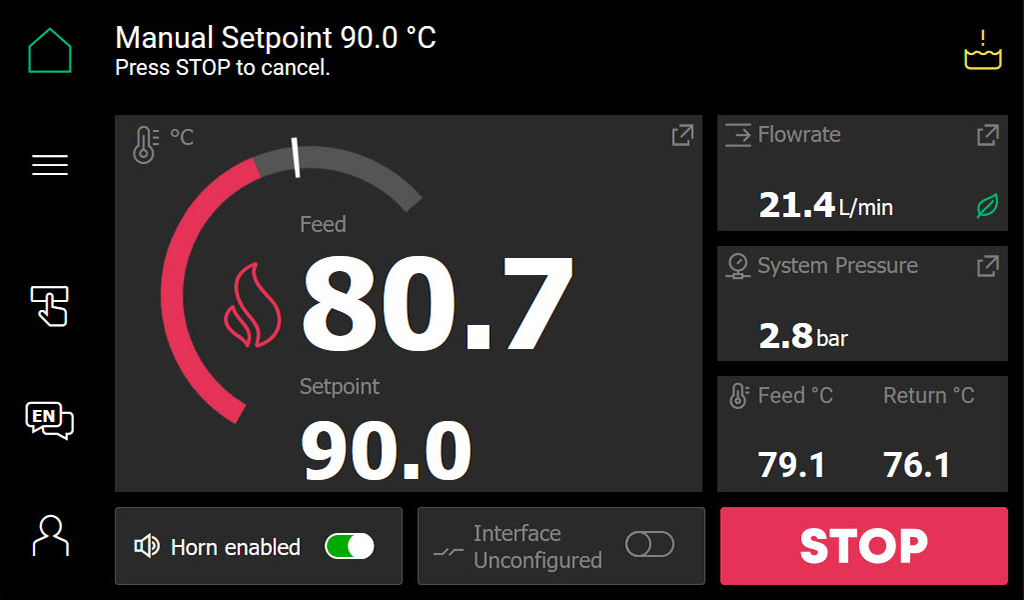

All operating data such as temperatures, pressures, flow rates, operating states, status messages, diagram data and data curves are available in the controller. IRIS continuously informs, reports and optimizes the operation of the temperature control unit.

In addition to local operation on the touchscreen, remote access is possible. Using a terminal device such as a phone, tablet or PC, you can access the web server integrated in the temperature controller via a web browser. The connection is made via LAN cable or via the WLAN adapter integrated in the controller. The operation here does not differ in any way from manual operation.

The model-based algorithms continuously summarize all available data and compare it with the current, expected behavior. This constant adaptation enables the overall system to provide optimum, uninterrupted and reliable temperature and flow control and reliable monitoring of the process.

Digital intelligence

Flexible connectivity

Simple and intuitive operation

Everything at a glance

Main Features

- Modular, extendable design

- Control voltage of 24 V DC

- Intuitive 7″ touch-screen interface for seamless user interaction

- Three user levels with configurable password protection

- Automatic actions for common operations (e.g. mould evacuation, end of shift)

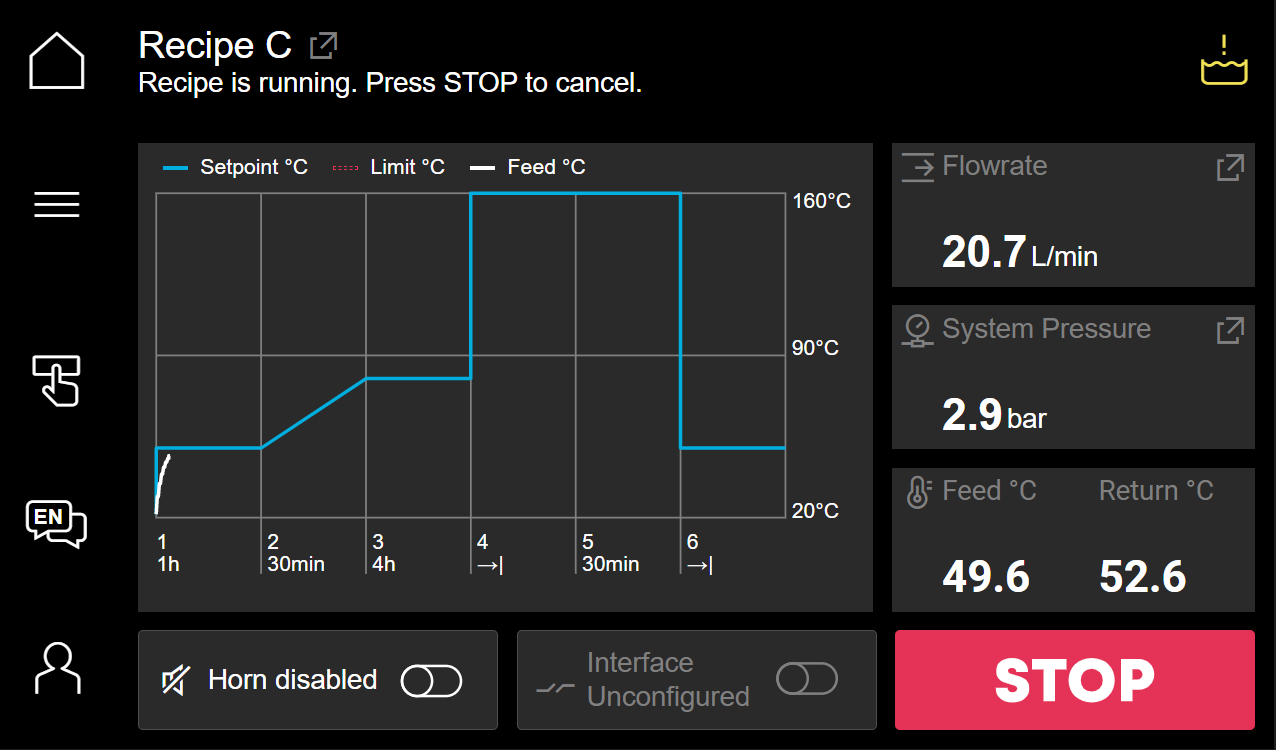

- User-defined time-resolved recipes

- Custom-engineered adaptive control algorithms

- Flexible timer functionality (coming soon)

- Down- and upload of controller configuration (coming soon)

Data Availability

- Expressive list of messages (informations, warnings, errors)

- Visualisation of time-resolved recipes (preview and live)

- Live visualisation of sensor data (coming soon)

- Downloadable data and error logs (coming soon)

Focus on Energy Efficiency

- Pump power on demand by full integration of variable-frequency drive in control logic

- Three pump-control modes to fit every demand

- Intelligent, coordinated heating and cooling

- Dedicated energy-monitoring screen with resettable counters (coming soon)

Localisation

- Physical units, date format, and accessibility features freely configurable

- Languages: EN, DE, FR, IT, ES

Interfaces and Protocols

- EtherNet

OPC-UA (coming soon)

REST API (HTTP) (coming soon)

WLAN (coming soon)

Remote UI (screen as on controller) (coming soon) - USB

Firmware update Download of error and data logs (coming soon)

Other interfaces require an extension module:

- I/O Module 1

CAN, RS-485, RS-232, Current Loop - I/O Module 2

Profibus, Profinet, EtherNet/IP - I/O Module 3 (coming soon)

Digital inputs (24 V DC) and outputs (up to 230 V)

Analogue inputs and outputs (0-10 V, 0/4-20 mA)

External temperature measurement: all thermocouple types and Pt resistors (up to 4-wire)

About Tool-Temp

For over 50 years Tool-Temp has been developing and manufacturing temperature control and cooling equipment in Switzerland for all manufacturing industries as an owner-managed company.

Tool-Temp, as one of the leading manufacturers of temperature control and cooling equipment, is represented on all continents worldwide and has its own presence with 16 Tool-Temp companies. Tool-Temp products are used in all processing industries: plastics, die casting, injection molding, extrusion, rubber, silicone, chemical, pharmaceutical, food, printing, lamination, textile and wood.