A look behind the scenes of development

A look behind the scenes of development

Last year, Tool-Temp presented the MATIC product line at various international trade fairs – a smart and intelligent range of temperature control units that meet all the requirements of automated production environments.

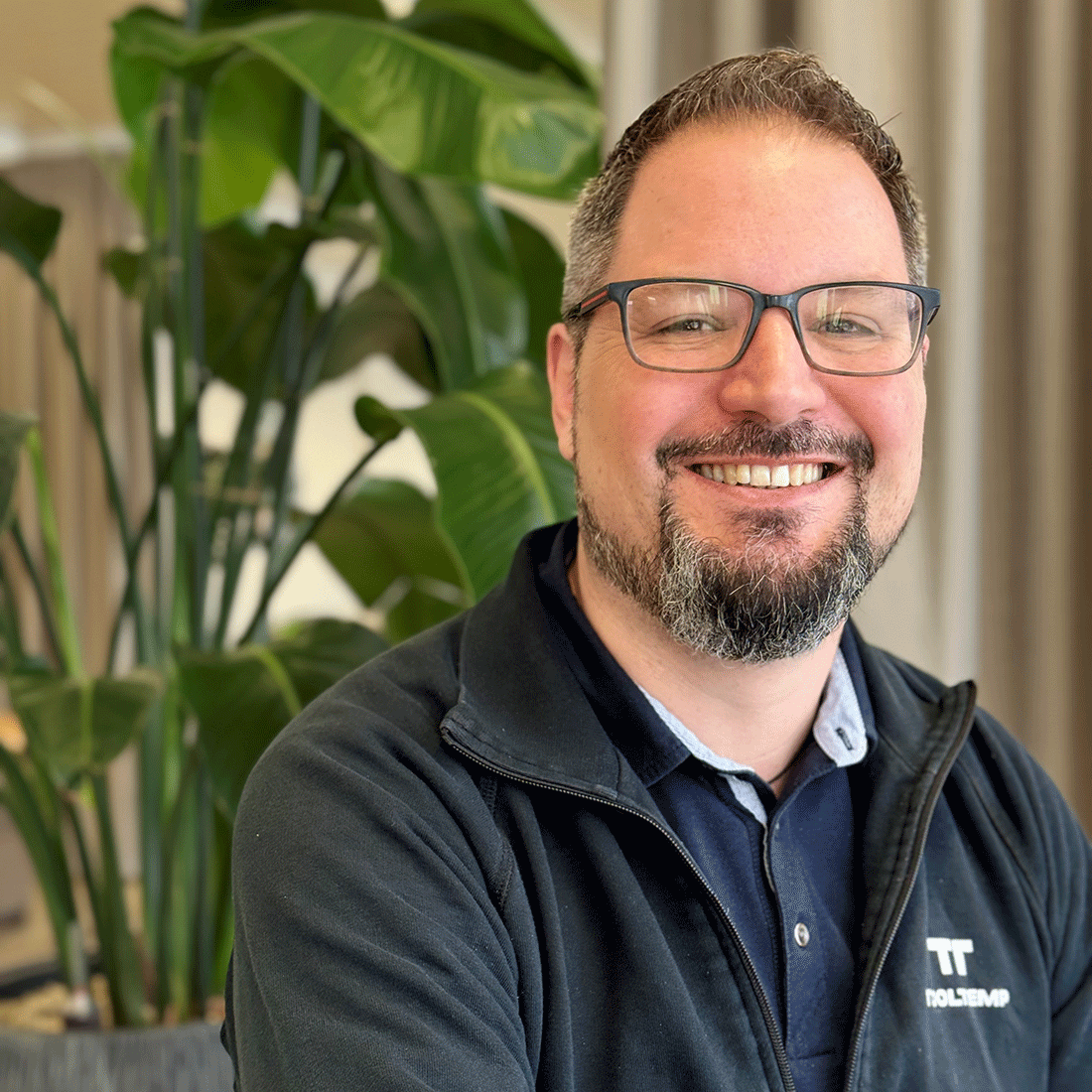

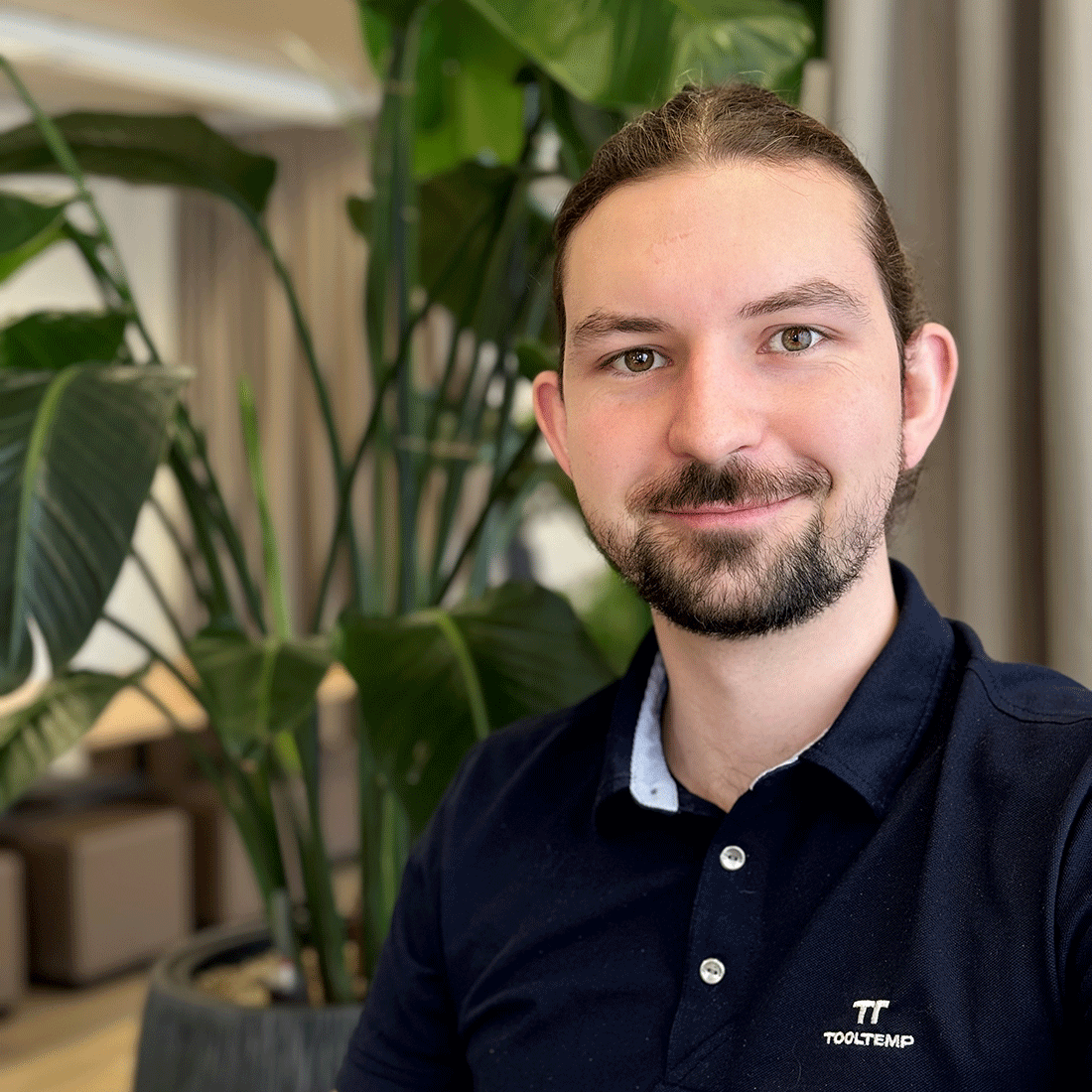

Our entire development team, led by Jonas Asprion, Chief Technology Officer (CTO), has done an outstanding job. In this interview, we offer the opportunity to take a look behind the scenes of our development department. Roger Loriol and GianAndrea Müller are two of our creative minds behind the MATIC product line. They talk about the technical challenges and the development process of the MATIC product line and give an insight into the dedicated work of our development staff, who work day in and day out to get the best out of temperature control technology.

Roger Loriol has been responsible for the development of the user interface (UI) for the new MATIC series since 2022 and is also intensively involved with the user experience (UX). In addition to the programming itself, he also takes care of the operating concept.

GianAndrea Müller has worked on the control of temperature control units since joining the company. This includes a fundamental physical understanding of how all types of equipment work. This is the basis for the development of the operating logic and control algorithms for the new MATIC line and the actual implementation on the IRIS controller.

What exactly are user interface (UI) and user experience (UX)? How do they affect the usability of the device?

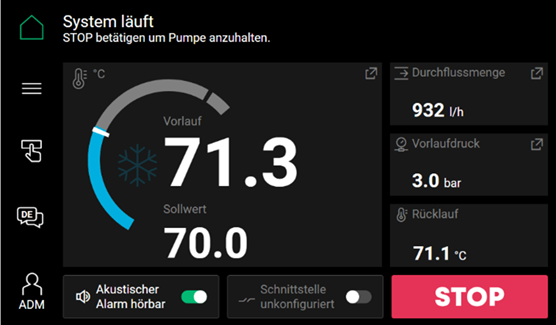

Roger Loriol: UI means “user interface”. The UI is the interface through which the user interacts with a machine or a website. In the case of our machines, this used to be the entire cabinet door with the controller and all the switches and lights. Now there is a touch screen that can be used to control all the functions of the machine. UX can be translated as “user experience”. UX refers to the totality of impressions a user has when interacting with a product. The UI plays a crucial role in this. UX design aims to make the user experience as positive, efficient and satisfying as possible.

We have always received positive feedback about the operation of our units – simple and straightforward. We wanted to keep it that way with the new IRIS controller in the MATIC range. That’s why, when developing the user interface, we always focused on simple and intuitive operation to create a positive UX.

How did the process of developing the UI work?

Roger Loriol: We started by interviewing some long-standing customers. The interviews revealed exciting opportunities to fill gaps in existing functionality. Customers responded very positively to this experience.

The second step was to develop the foundations for the new UI. This generated a lot of ideas on how to make the advanced features of the MATIC units and the new controller easy to use.

How was the user-friendliness/usability of the UI tested?

Roger Loriol: Once the design phase was complete, we presented an initial version of the UI to various test users and incorporated their valuable feedback into the further development. In collaboration with the management, we also did this online with our branches. Last but not least, the demo version of the UI was also presented to our customers at various trade fairs.

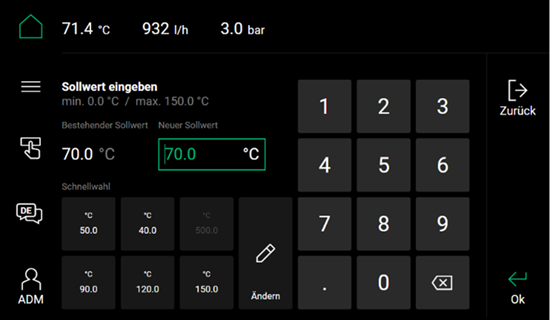

Two examples of the new controller’s user interface

How is the new IRIS controller different?

GianAndrea Müller: The main difference lies in the centralised intelligence. This means that all sensor information flows together and is combined. The frequency converter installed as standard in the MATIC models is also fully integrated into our control system. This enables us to continuously monitor and better control the appliance. As the entire controller is modular in design and has reserves of computing power, we are prepared for any new requirements that may arise in the future.

What was required to achieve this?

GianAndrea Müller: On the control technology side, we first needed a clear understanding of our devices. To do this, I derived the current operating logic from our electrical schematics, created fluidic schematics for all devices in the MATIC series and defined a comprehensive measurement campaign, which we were able to implement with the active support of Jonas Asprion (CTO) and production. We used this measurement data and the physical correlations to create a mathematical simulation model of our appliances and potential consumers. This “digital twin” now allows us to test different operating conditions within seconds, which would otherwise take days and weeks with a test setup.

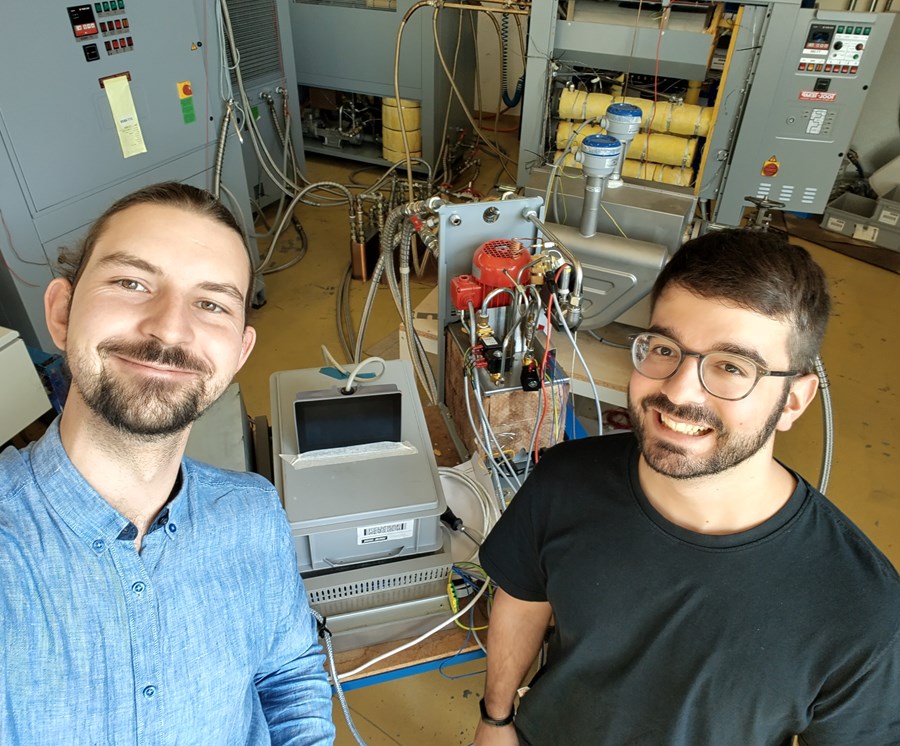

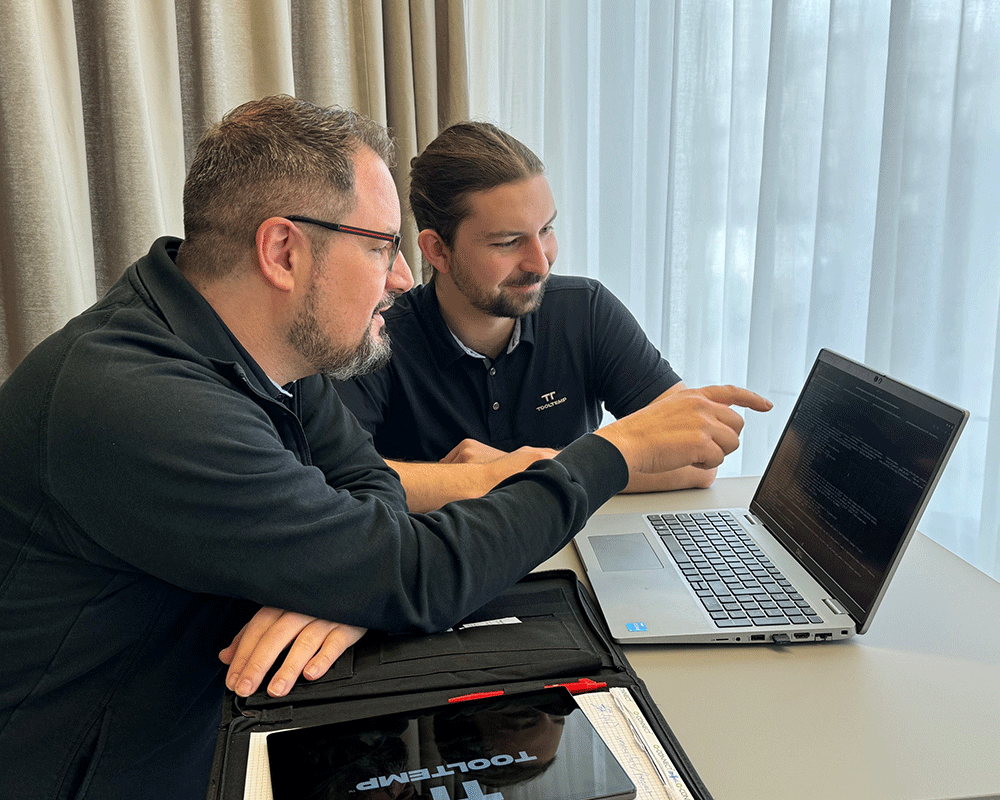

GianAndrea Müller and Roger Loriol brainstorming

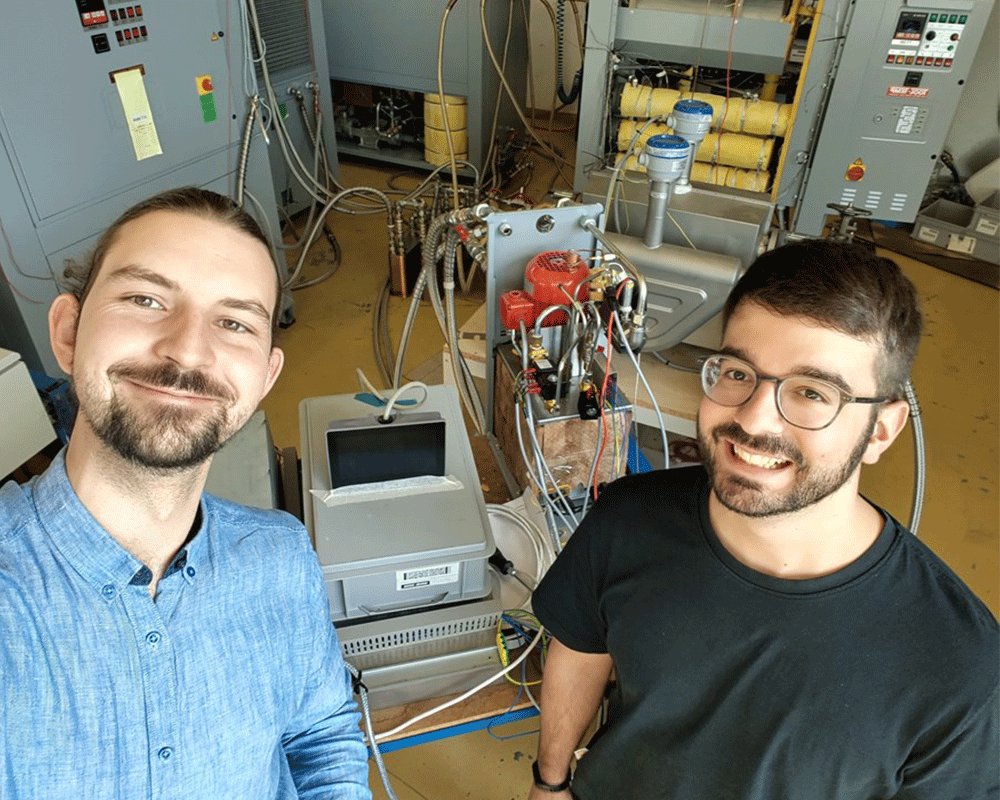

GianAndrea and Jonas Meier in front of the first test setup for MATIC