Tool-Temp temperature control units contribute to the delicious taste of Swiss chocolate

Tool-Temp temperature control units contribute to the delicious taste of Swiss chocolate

Tool-Temp AG spoke with Mr Robin Auer, Head of Marketing at Chocolat Stella Bernrain, about the production of chocolate – from the grains of cocoa beans to the crucial temperature control of the chocolate, as well as about developments and innovations in chocolate production.

The Swiss manufacturer of premium chocolate, Chocolat Stella Bernrain, produces high-quality chocolate specialities for corporate customers around the world. Tool-Temp temperature control units are used to simplify the manufacturing process and help improve production quality. Founded in 1932 and based in Kreuzlingen and Giubiasco, Switzerland, Chocolat Stella Bernrain is committed to sustainability in both the sourcing of raw materials and production, and is dedicated to genuine Swiss quality in its chocolate specialties.

1. How has Chocolat Stella Bernrain developed over the more than 90 years of its existence?

Chocolat Bernrain AG was founded in 1932 as a manufacturing company and progressively expanded into an industrial production company. In 1980, Chocolat Stella SA, located in Giubiasco, was taken over by Chocolat Bernrain AG. Since then, the two companies have been working together under the name Chocolat Stella Bernrain. The third-generation family member, Monica Müller, has been leading the company since 2007. Under her leadership, the new factory in Giubiasco was built in 2013 and an enlargement in Kreuzlingen followed in 2021, thereby doubling the previous production area. Today, the company counts around approximately 200 employees in both locations.

2. How has your product range changed over time, and what innovative chocolate products do you offer today?

Starting with just a few chocolate products, the company has expanded its range over the years. During this time, Stella Bernrain has proven its innovative strength once again. In 1991, the company committed itself to sustainable production and launched the first organic and Fairtrade certified chocolates. In the last few years, a range of vegan chocolates has been launched and continues to be sold successfully. Today, sustainable packaging solutions are increasingly in demand. This is why Chocolat Bernrain offers compostable films. The company also aims to reduce the amount of packaging material by using single-layer packaging for products that are traditionally packaged in two layers. The used paper-based packaging material offers the same essential sealing properties as conventional products.

3. Why is maintenance of the optimum chocolate temperature crucial for the end product?

The maintenance of the optimum temperature is essential in the production of chocolate. The right temperature influences the texture, shine and flavor of the finished product. Precise temperature control ensures the perfect consistency and shine of the chocolate. Moreover, the right temperature allows the chocolate to develop its full flavor, ensuring a delicious taste. In short, temperature control is crucial for producing the best possible chocolate which everyone wants to enjoy.

4. What role do Tool-Temp temperature control units play in your daily process or product quality requirements?

We use the temperature control unit to heat some of our conches and to melt blocks of cocoa mass. The precise temperature control as explained above is very important to ensure the high quality of our products.

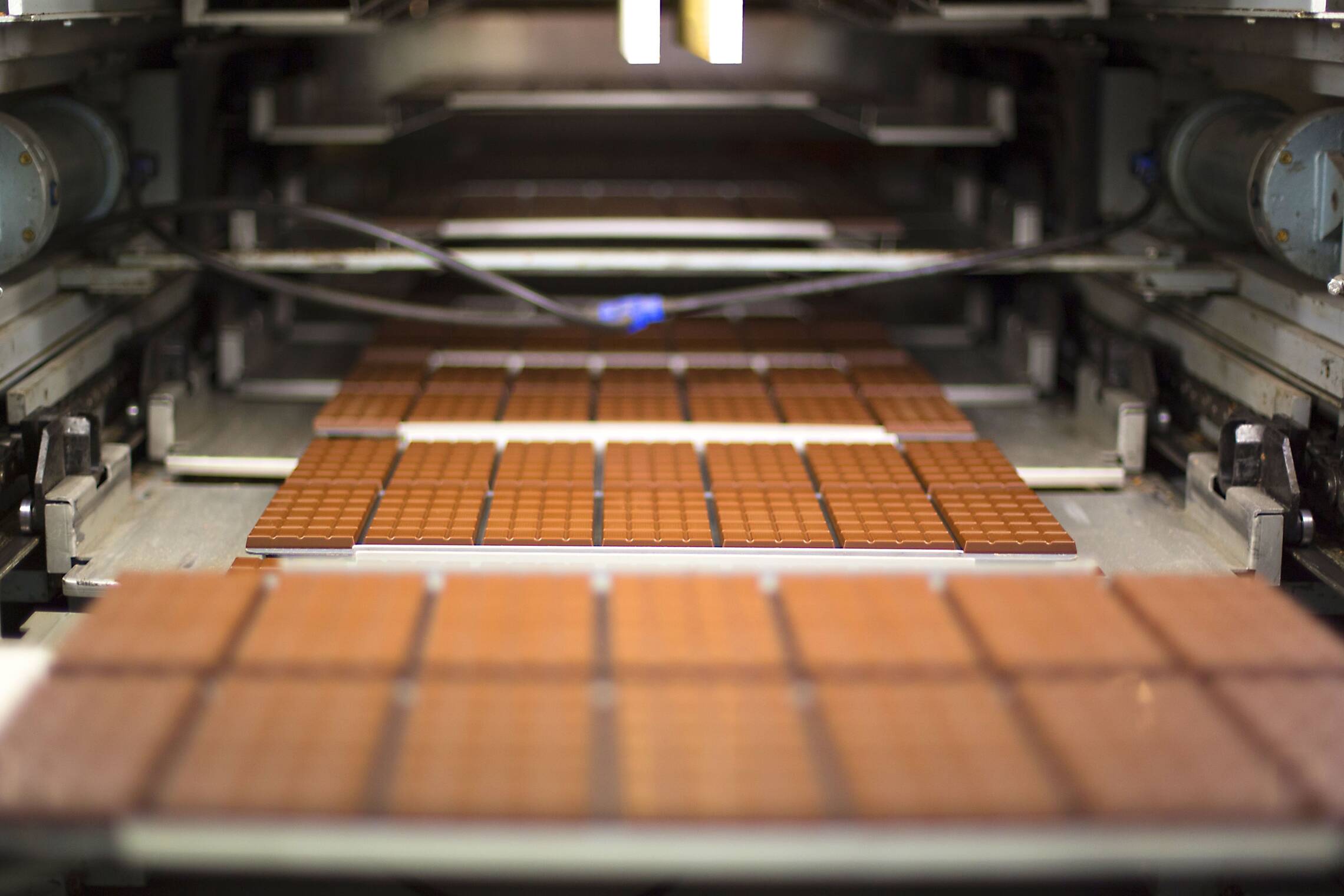

Production of chocolate bars at Chocolat Bernrain AG.

Chocolate production at Chocolat Bernrain AG.

5. How long does it take approximately take from the cocoa harvest until the finished chocolate arrives to a consumer?

It can take almost a year from the time the cocoa is harvested to the time the chocolate reaches the customer. Harvesting usually takes place twice a year. After the harvest, it can take several weeks to months for the cocoa to reach the factory for processing, depending on transport options and demand. The actual chocolate production takes between 24 and 72 hours, depending on how long the chocolate is being conched. The final moulding process into bars or pralines takes a very short time as we can mould over 1,500 kg of chocolate per hour into bars.

6. How many hours per day are the Tool-Temp temperature control units in operation?

The conching devices operate around the clock. The temperature control unit for the melter automatically switches off when the job is finished. This was very easy to implement as the units have remote start/stop.

7. Is there anything else you would like to add about your experience with Tool-Temp temperature control units?

“We are very happy with the temperature control units. The customer service is excellent and we receive very detailed information when any questions arise. In the event of a repair, a technician is quickly on site,” says Mr. Roger Näf, Head of Technology, about the use of Tool-Temp temperature control units in their production.

A look behind the scenes of development

A look behind the scenes of development

Last year, Tool-Temp presented the MATIC product line at various international trade fairs – a smart and intelligent range of temperature control units that meet all the requirements of automated production environments.

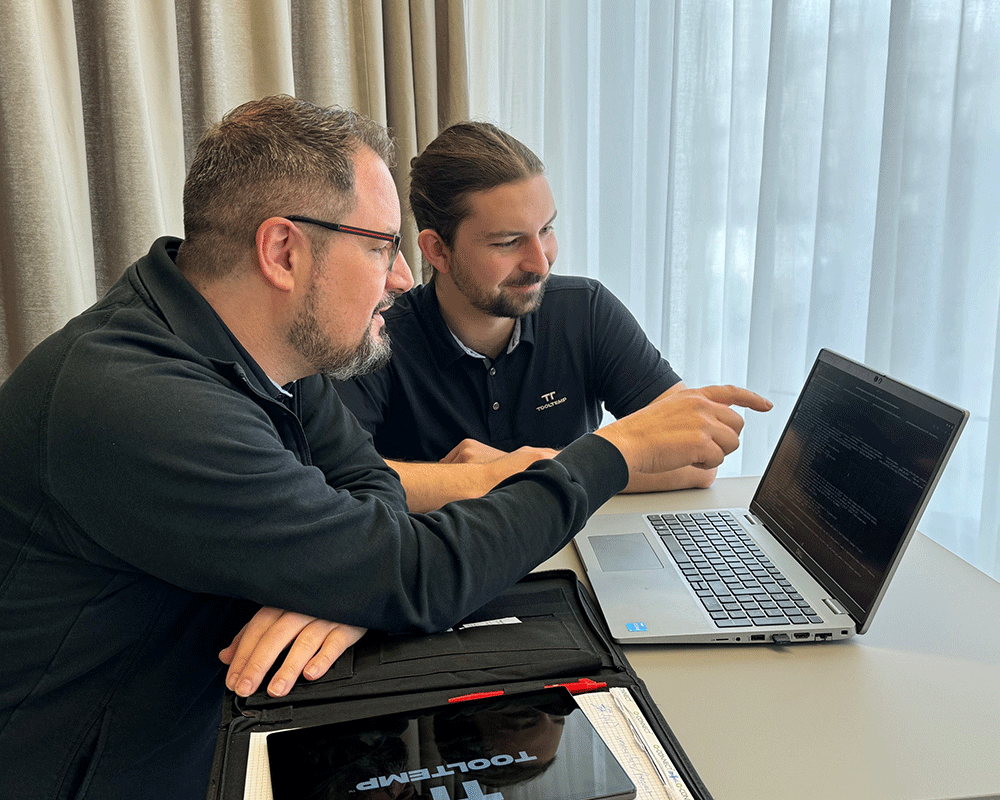

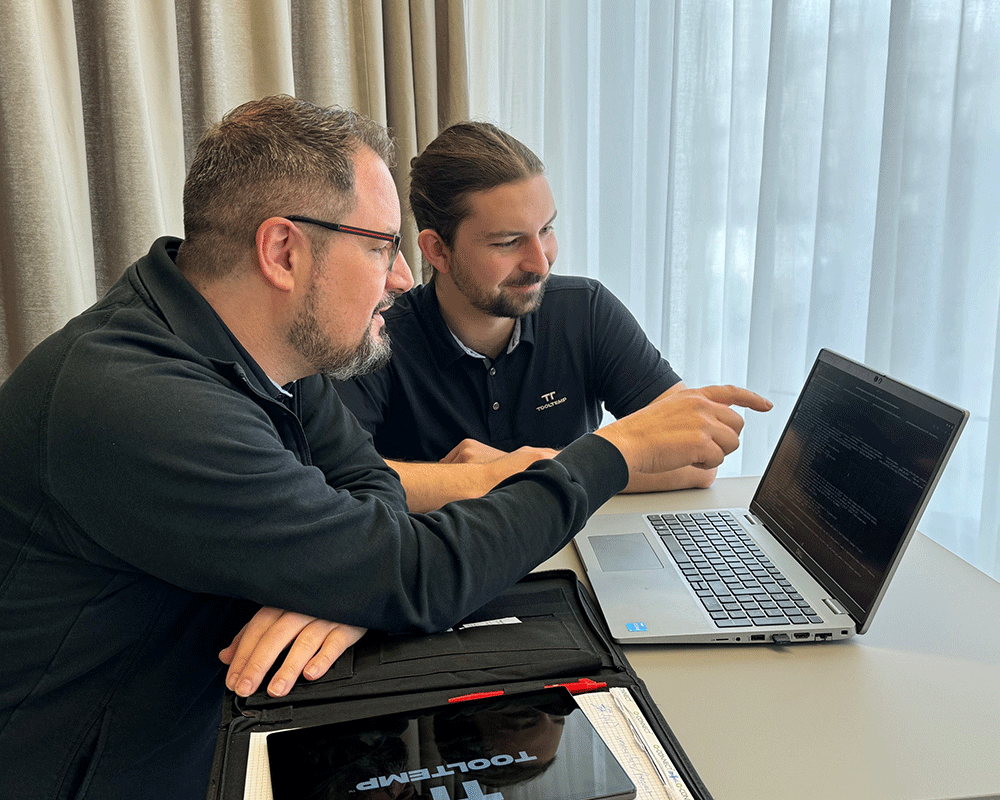

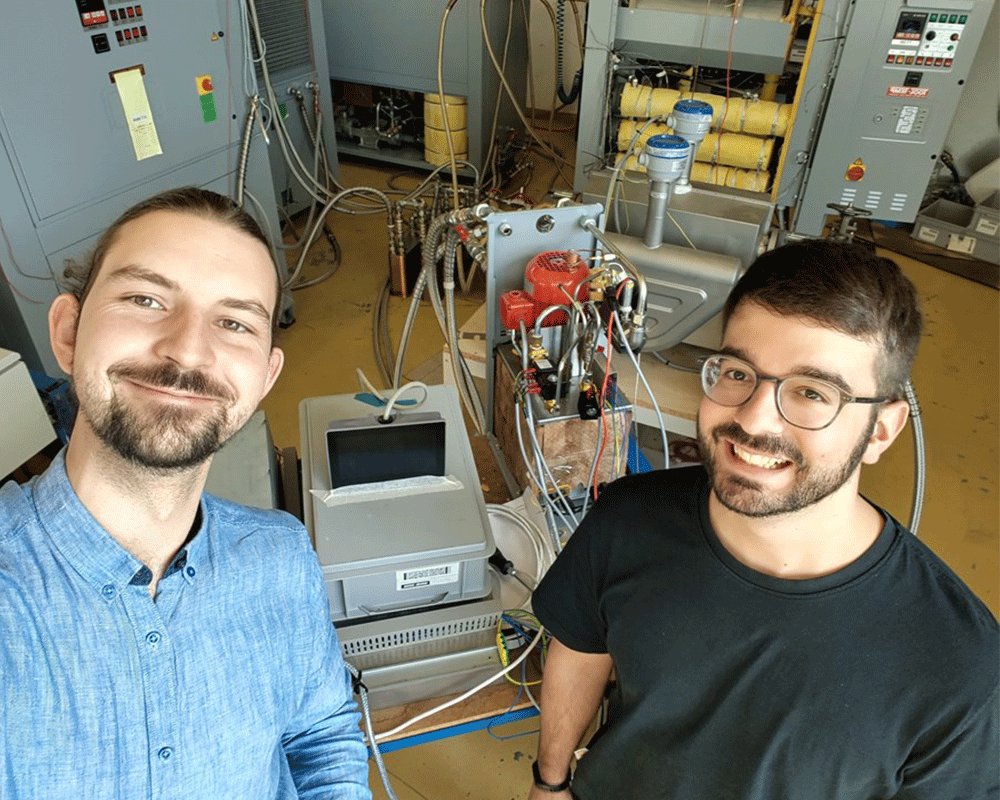

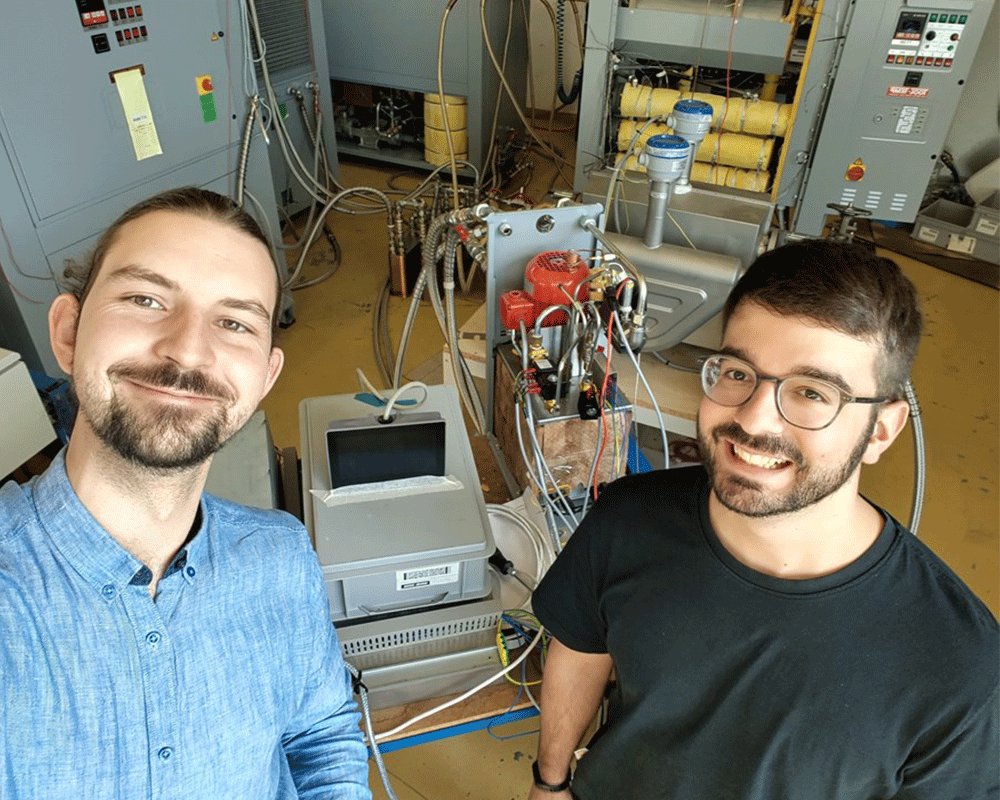

Our entire development team, led by Jonas Asprion, Chief Technology Officer (CTO), has done an outstanding job. In this interview, we offer the opportunity to take a look behind the scenes of our development department. Roger Loriol and GianAndrea Müller are two of our creative minds behind the MATIC product line. They talk about the technical challenges and the development process of the MATIC product line and give an insight into the dedicated work of our development staff, who work day in and day out to get the best out of temperature control technology.

Roger Loriol has been responsible for the development of the user interface (UI) for the new MATIC series since 2022 and is also intensively involved with the user experience (UX). In addition to the programming itself, he also takes care of the operating concept.

GianAndrea Müller has worked on the control of temperature control units since joining the company. This includes a fundamental physical understanding of how all types of equipment work. This is the basis for the development of the operating logic and control algorithms for the new MATIC line and the actual implementation on the IRIS controller.

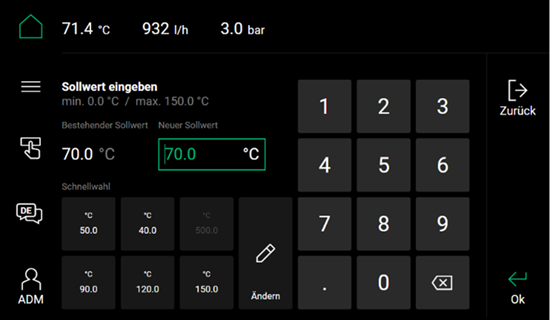

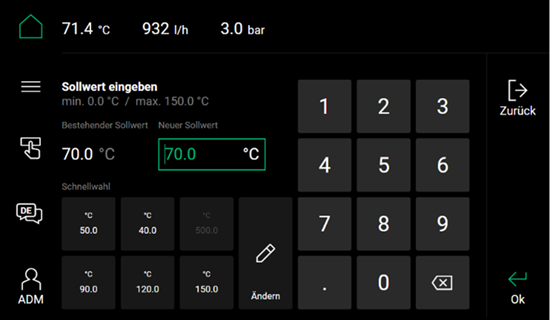

What exactly are user interface (UI) and user experience (UX)? How do they affect the usability of the device?

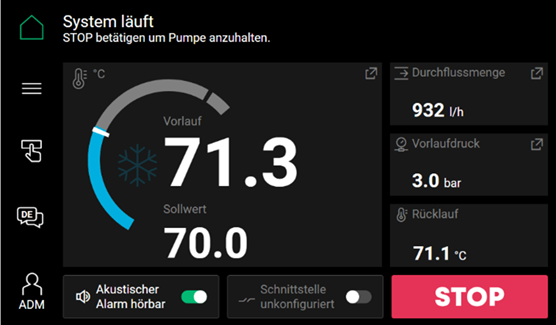

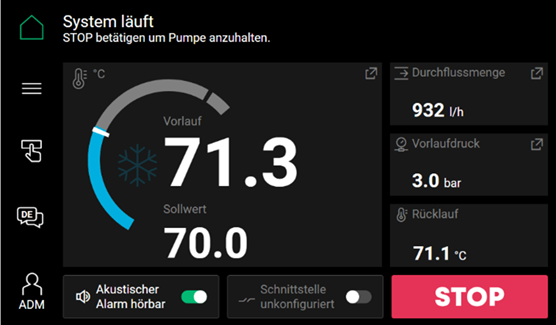

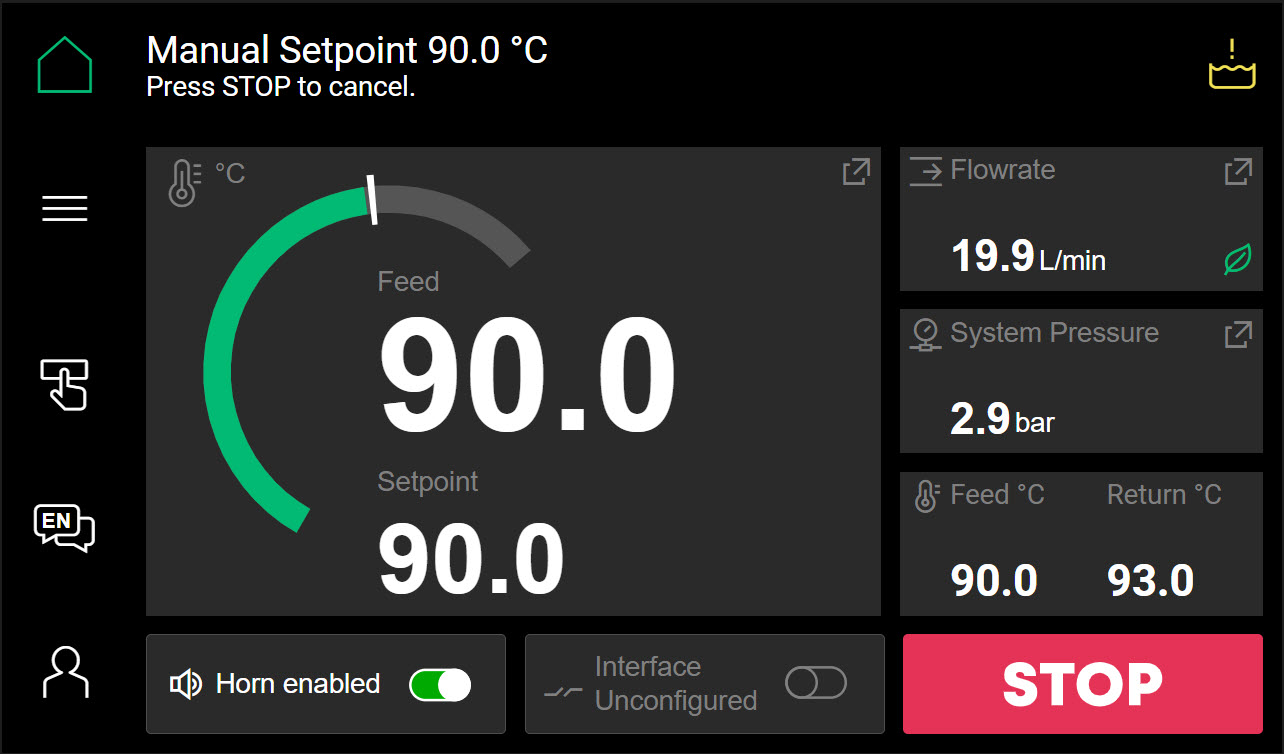

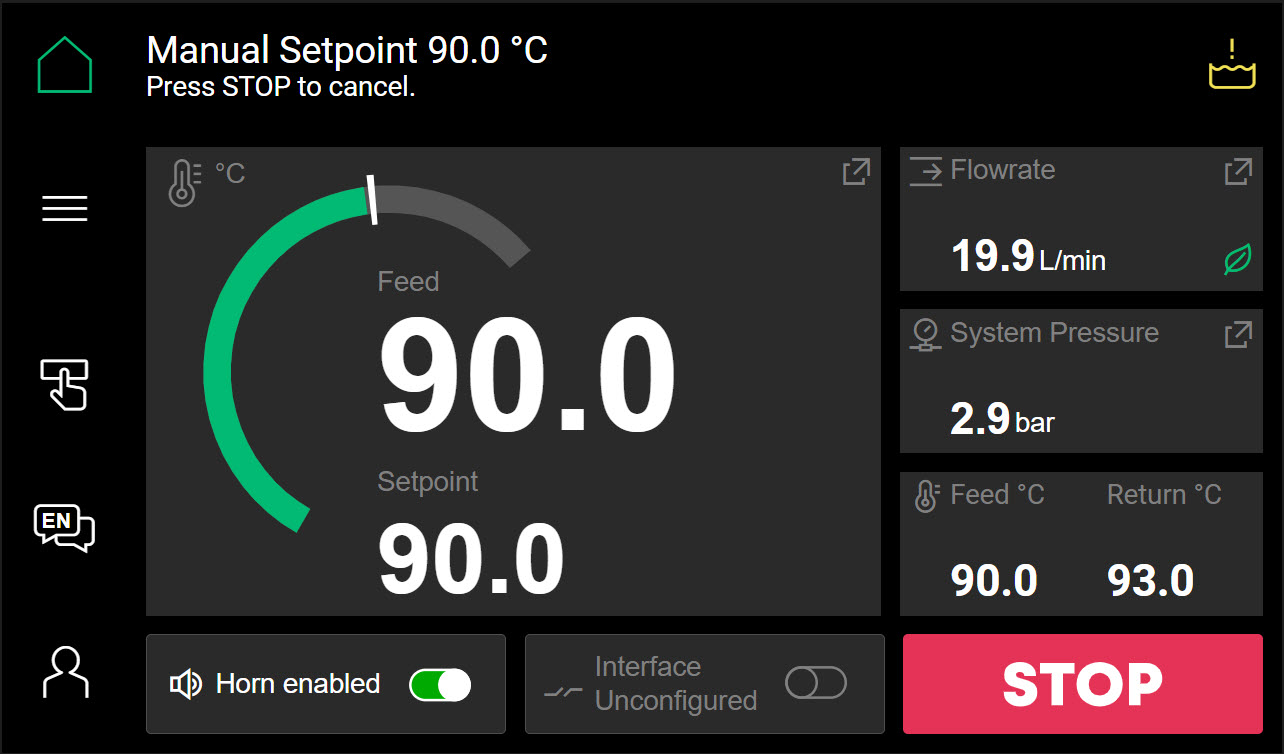

Roger Loriol: UI means “user interface”. The UI is the interface through which the user interacts with a machine or a website. In the case of our machines, this used to be the entire cabinet door with the controller and all the switches and lights. Now there is a touch screen that can be used to control all the functions of the machine. UX can be translated as “user experience”. UX refers to the totality of impressions a user has when interacting with a product. The UI plays a crucial role in this. UX design aims to make the user experience as positive, efficient and satisfying as possible.

We have always received positive feedback about the operation of our units – simple and straightforward. We wanted to keep it that way with the new IRIS controller in the MATIC range. That’s why, when developing the user interface, we always focused on simple and intuitive operation to create a positive UX.

How did the process of developing the UI work?

Roger Loriol: We started by interviewing some long-standing customers. The interviews revealed exciting opportunities to fill gaps in existing functionality. Customers responded very positively to this experience.

The second step was to develop the foundations for the new UI. This generated a lot of ideas on how to make the advanced features of the MATIC units and the new controller easy to use.

How was the user-friendliness/usability of the UI tested?

Roger Loriol: Once the design phase was complete, we presented an initial version of the UI to various test users and incorporated their valuable feedback into the further development. In collaboration with the management, we also did this online with our branches. Last but not least, the demo version of the UI was also presented to our customers at various trade fairs.

Two examples of the new controller’s user interface

How is the new IRIS controller different?

GianAndrea Müller: The main difference lies in the centralised intelligence. This means that all sensor information flows together and is combined. The frequency converter installed as standard in the MATIC models is also fully integrated into our control system. This enables us to continuously monitor and better control the appliance. As the entire controller is modular in design and has reserves of computing power, we are prepared for any new requirements that may arise in the future.

What was required to achieve this?

GianAndrea Müller: On the control technology side, we first needed a clear understanding of our devices. To do this, I derived the current operating logic from our electrical schematics, created fluidic schematics for all devices in the MATIC series and defined a comprehensive measurement campaign, which we were able to implement with the active support of Jonas Asprion (CTO) and production. We used this measurement data and the physical correlations to create a mathematical simulation model of our appliances and potential consumers. This “digital twin” now allows us to test different operating conditions within seconds, which would otherwise take days and weeks with a test setup.

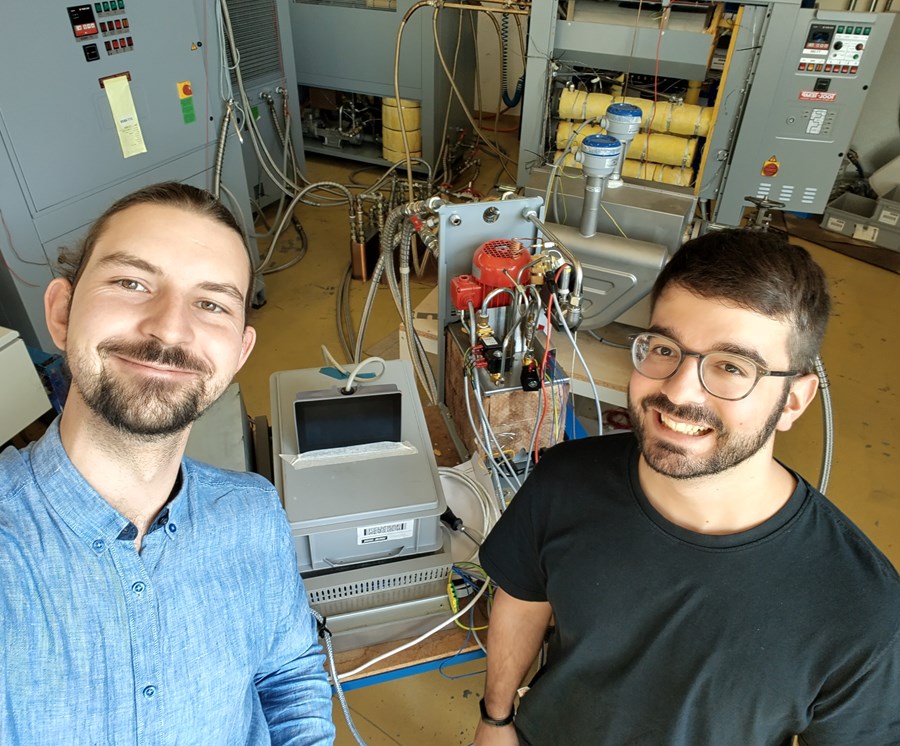

GianAndrea Müller and Roger Loriol brainstorming

GianAndrea and Jonas Meier in front of the first test setup for MATIC

Tool-Temp AG is delivers positive results after Euroguss 2024

Tool-Temp AG is delivers positive results after Euroguss 2024

A total of 634 exhibitors from 33 countries showcased the latest technological trends, innovative processes, and product innovations across the entire value chain of die casting to approximately 14,341 industry professionals at Euroguss 2024.

At the exhibition, Tool-Temp AG once again presented their latest product line, MATIC, specifically tailored to the needs of a digitally connected production environment. This innovation generated significant interest among attendees, as precise temperature control and uniform temperature distribution throughout the entire die casting process play a crucial role.

In addition to precise temperature control, Tool-Temp AG’s temperature control units offer future owners a range of other benefits. These include a durable magnetically coupled pump developed in-house, accurate temperature measurements at the tool, clear digital flow measurement, and pressure indication on the device. The robust industrial design also ensures reliable operation under the demanding conditions of the die casting industry, guaranteeing long-lasting use for customers.

Interested trade show visitors were introduced to the temperature control units through exhibition displays and detailed explanations. “We are delighted with the outcome of the event and the positive feedback from our customers. The high number of visitors to our booth confirms the strong interest in comprehensive temperature control solutions in the die casting sector. Particularly, the new MATIC temperature control unit line with the innovative IRIS controller garnered significant attention from industry professionals. Valuable new connections were established, and existing customer relationships were deepened during the three days of the exhibition. The extremely positive response from trade show attendees has once again exceeded our expectations. We thank everyone for the valuable discussions and the lively exchange of experiences,” concludes Luca Pellegrino, Director of Global Sales.

New management at Tool-Temp Asia Pte Ltd

New management at Tool-Temp Asia Pte Ltd

On 1 January 2024, the Swiss Headquarters Tool-Temp AG will acquire 100% of the shares of Tool-Temp Asia Pte Ltd, based in Singapore. Dereck Tan will take over the operational management of the successful Asian branch as the new General Manager.

The long-time shareholder, Hubert Nerlich, has transferred his shares to the Headquarters in Switzerland. However, he will continue to support Tool-Temp Asia Pte Ltd as a Director (Member of the Board).

We are delighted to announce that Dereck Tan, who has been with Tool-Temp for many years in Business Development and Sales, has joined Tool-Temp Asia Pte Ltd as General Manager. In his new role he will be responsible for the business development of Tool-Temp Asia Pte Ltd with its subsidiaries in China and Taiwan. “We wish Dereck Tan every success in his new role and look forward to working with him,” says Marco Pellegrino, Chief Sales Officer of Tool-Temp AG.

With this step, Tool-Temp AG is investing in an important and promising market and is looking forward to the further development and expansion of its business in Asia. Tool-Temp Asia Pte Ltd maintains a central warehouse with new equipment to serve customers in ASEAN as well as China, Taiwan and India. Cooperation with local distributors will be intensified and expanded.

Dereck Tan, General Manager Tool-Temp Asia Pte Ltd / Jasmine Koller, CEO Tool-Temp AG (Headquarter) / Marco Pellegrino, CSO Tool-Temp AG (Headquarter)

Tool-Temp AG establishes presence in Dubai with the innovative MATIC product line

Tool-Temp AG establishes presence in Dubai with the innovative MATIC product line

The leading trade fair in the Middle East, ArabPlast 2023, took place from 13 to 15 December 2023 in Dubai, United Arab Emirates. As the 16th international trade fair for the plastics, recycling, petrochemical, packaging and rubber industries, the ArabPlast 2023 provided a unique opportunity for cross-industry exchange and cooperation. Companies from various segments of the plastics industry had the opportunity to benefit from each other and develop potential partnerships.

With the launch of the new branch in Dubai, Tool-Temp Middle East & Africa, and the innovative MATIC product line, ArabPlast 2023 was an important event for Tool-Temp AG. The precise temperature control and exceptional efficiency provided by the in-house developed IRIS controller were particularly appreciated by visitors and experts. The MATIC temperature control units presented by Tool-Temp AG not only met with great interest, but also generated numerous enquiries for customised solutions.

This positive response shows that the temperature control units from Tool-Temp AG offer clear added value for the plastics industry thanks to state-of-the-art technologies and, with the MATIC product line, make an important contribution to efficient and future-orientated temperature control.

The establishment of the new branch in Dubai in this emerging economic centre underlines Tool-Temp’s commitment to global presence and customer proximity. Tool-Temp is looking forward to intensifying the contacts made during ArabPlast 2023 and offering state-of-the-art temperature control solutions in the Dubai region. In addition, this opens up promising prospects for future cooperation and joint success and marks an encouraging start for Tool-Temp MEA.

Tool-Temp AG continues to grow

Tool-Temp AG continues to grow

Tool-Temp AG is expanding: On 1 December, the Swiss specialist and manufacturer of temperature control and cooling units will open a new branch in Dubai, United Arab Emirates. The Swiss company is thus responding to the growing global demand for its products and developments.

Tool-Temp AG is further expanding its business activities and strengthening its international presence in the Middle East and Africa. All customers and interested parties in these regions will be supported from there. Manufacturing companies from a wide range of industries will have access to the Swiss manufacturer’s first-class temperature control and cooling equipment. However, the production of the units for the whole world remains at the headquarters of Tool-Temp AG Sulgen, from where the units are delivered to all branches and from there to the end users. This ensures that all products are designed and built to the same high Swiss quality standards.

Saad Ahsan is responsible for the new Tool-Temp MEA branch. With many years of experience in a well-known international engineering and technology group, as Technical Sales Advisor MEA he has extensive knowledge in business strategy, business development, sales excellence, sales management, aftermarket sales and leadership. “We are very excited about the expansion of the Tool-Temp family. The manufacturing industry in the Arab region is growing and having a branch in the heart of this region was a logical step for us,” said Marco Pellegrino, Chief Sales Officer of Tool-Temp AG. “The new location will not only allow us to reach more customers and prospects, it will also enable us to provide our existing customers with even more individual and personalised support and further improve our response times.”

Tool-Temp AG looks back on successful Fakuma 2023

Tool-Temp AG looks back on successful Fakuma 2023

The 28th Fakuma, International Trade Fair for Plastics Processing, successfully took place from 17 to 21 October 2023. With 1,636 exhibitors, the trade fair was a fully booked celebration of plastics. A full house, satisfied exhibitors and 39,343 enthusiastic trade visitors made Friedrichshafen the center of the plastics industry – at least for these five days.

Tool-Temp AG was pleased to present the new MATIC range of temperature control units, designed to meet all the requirements of a digitally networked production environment. The interest in this innovation “made by Tool-Temp” was enormous, because also in the plastics industry, optimal temperature control and even temperature distribution throughout the entire processing process play a decisive role. The MATIC product line is equipped with the new IRIS controller developed by Tool-Temp and is modularly expandable.

During the five days of the fair, valuable new contacts were made and existing relationships were maintained once more. The successful participation at the fair has proved that personal contact is the basis for good cooperation, especially when it comes to successfully implementing projects together! “The extremely positive response of the trade fair visitors once again exceeded our expectations. The high number of stand visitors confirms the great interest in our complete temperature control solutions in the industry as well as in our new MATIC temperature control units which take production processes to the next level”, says Marco Pellegrino, CSO of Tool-Temp. ” Industry 4.0 is another important step into the future of temperature control processes and the expansion of our product range for our customers. We are grateful for the valuable discussions and the lively exchange of experiences,” concludes Pellegrino.

Tool-Temp staff at the booth

The modern booth with various temperature controle units

The new MATIC range - temperature control made easy

The new MATIC range - temperature control made easy

With the MATIC and CLASSIC series, the Swiss company Tool-Temp AG is modernising its existing range of temperature controllers in terms of function and design. With the launch of the new MATIC series, Sulgen-based Tool-Temp AG responds to Industry 4.0, which means that there are “almost” no limits to temperature control. The CLASSIC series, the proven classic in a new design, is characterised by its durability and is the ideal solution when the temperature control unit’s range of tasks is limited to its core function, the control of the circulating medium.

The new temperature control units of the MATIC series meet all the requirements of production environments leveraging industrial networks. The entire MATIC product line is equipped with the new IRIS controller developed by Tool-Temp. It offers a broad range of connectivity features and is modularly expandable. The IRIS controller covers the timetested serial and digital/analogue interfaces, classical fieldbus protocols, as well as the current state-of-the-art-industrial ethernet (Profinet, EtherNet/IP).

The MATIC temperature control units focus on energy efficiency. The energy-saving eco mode leverages the latest-generation variable-frequency drive installed in every MATIC unit. Intelligent and predictive temperature control prevents unnecessary energy expenses for heating and cooling. All the while the proven immersed heaters offer a 100% conversion efficiency. In short, MATIC reduces both the energy consumption of the temperature control processes and downtimes to a minimum.

Chief Operating Officer, Serge Koller, is convinced of the MATIC line of units and explains: “Users can look forward to a new, self-developed controller with an easy-to-use touchscreen display and a more modern design. The IRIS controller continuously informs, reports and optimises the operation of the temperature control unit. In addition, the cable pull can be attached to either the front or the rear of the unit, which offers the user advantages in operation. In future, the customer will also be able to decide on the protection class – IP44 or IP54 – of the housing. Last but not least, the customer can save energy and money thanks to the newly integrated frequency converter.”

Tool-Temps temperature control units have been used successfully in a wide range of industries for 50 years. Moulds and tools can be brought to the required temperature with temperature control units. In addition, they ensure a stable heat balance throughout the entire production process, which delays premature damage to moulds or tools and thus significantly increases service life. The temperature control units from Tool-Temp combine economic thinking, permanent and intelligent monitoring with troubleshooting as well as predictive and adapted control during the entire temperature control process.

Tool-Temp AG high-performance partner of Stüdli Plast AG

Tool-Temp AG high-performance partner of Stüdli Plast AG

Tool-Temp AG spoke with Ardit Kamberi, Technical Manager of Stüdli Plast AG, about the temperature control of injection moulds, the challenges in the production process and the development of the plastics industry.

Stüdli Plast AG, based in Romanshorn, Switzerland, has been supporting industrial customers in the realisation of technically demanding innovations in various industries since its foundation in 1954. Decades of tradition and the expertise gained from a wide range of projects make Stüdli Plast an innovative and efficient partner for all needs relating to plastic injection moulding. With its subsidiary Grischa Plast AG, Stüdli Plast has built up an even stronger sales network, which offers customers considerable advantages. The temperature control units of Tool-Temp AG are used throughout the production of plastic parts. A large number of units are already in daily use.

For many years Tool-Temp AG can count the company Stüdli Plast AG among its valued customers. Four TT-142 N pressurised water units are in daily use and recently a TT-54’500 cooling unit with a cooling capacity of 54 kW was put into operation.

1. What exactly is tempered at Stüdli Plast?

Injection moulded plastic parts weighing 3 – 3000 grams are tempered. The temperature range to be covered is between 140 °C and 220 °C. In addition to the heating function, cooling also plays a decisive role so that a constant temperature of 10 °C can be supplied to the production process and maintained. This is achieved with the Tool-Temp cooling unit TT-54’500.

2. What is the challenge of producing plastic parts?

Customer requirements are becoming increasingly greater. In addition to function, appearance is becoming more and more important. Producing a finished product from the granulate that meets the customer’s specifications is a major challenge. This requires reliable functioning of the peripherals, such as temperature control units. Only then can the narrow process windows be adhered to.

3. How has the plastics industry developed since your company was founded in 1954?

The plastics industry, like many other industries, has become much faster moving due to globalisation. Only a few weeks are needed from the 3D drawing to the finished product. The digital tools enable an almost perfect visualisation of the problems that could occur in the real process. In this way, these problems can already be counteracted in mould making. In recent years, the sustainability of the use of resources has developed significantly.

4. How do Tool-Temp units simplify your production process?

Due to the integrated controller and the strong pump power, the Tool-Temp units are easy to operate, reliable and very robust. This guarantees us a safer production of the products.

5. We are very grateful for our long-standing good business relationship. What brought you to Tool-Temp years ago?

The flexible and targeted cooperation led us to Tool-Temp. In addition, Tool-Temp is located close to Stüdli Plast. Tool-Temp has always been a high-performance partner for Stüdli Plast, even in situations where everything must be done quickly.

Tool-Temp AG mould tempering attracts interest at GIFA 2023

Tool-Temp AG mould tempering attracts interest at GIFA 2023

2’200 companies from 56 countries presented their products and innovations in the Düsseldorf exhibition halls from 12 to 16 June. 63’300 trade visitors from all over the world attended the world’s most important trade fair for foundry technology. Tool-Temp AG took the opportunity to present its new MATIC line of temperature control equipment, which covers all the requirements of a production environment with digital networking. A large number of visitors were interested in this innovation, as optimal temperature control and uniform temperature distribution during the entire process are crucial in die casting.

In addition to the precise temperature control, the Tool-Temp AG temperature control units will impress their future owners with other advantages such as the long-life magnetically coupled pump developed in-house, the precise temperature measurement at the mould and the clear digital flow measurement and pressure display on the unit. The robust industrial design, which can easily withstand the harsh everyday conditions of die casting, also guarantees the customer a long service life.

At the Tool-Temp stand, visitors were able to see for themselves the capabilities of the temperature control units and take a close look at the exhibits. Jasmine Koller, Managing Director of Tool-Temp AG, explains: “We are very satisfied with the outcome of the event as well as the positive customer feedback and the high number of visitors to the stand confirms the lively interest in complete temperature control solutions in the foundry industry. Our temperature control unit portfolio was very well received by the trade visitors. Especially the new MATIC temperature control unit line with the new IRIS controller was of great interest.”

During the five days of the show, very good new contacts were made and existing customer relationships were cultivated. “We are grateful for the many valuable discussions and the lively exchange of experiences. The extremely positive response from visitors exceeded our expectations and encourages us to continue investing in our smart and intelligent temperature control solutions for production plants, which are perfectly tailored to our customers’ requirements,” concludes Jasmine Koller.