Tool-Temp temperature control units contribute to the delicious taste of Swiss chocolate

Tool-Temp temperature control units contribute to the delicious taste of Swiss chocolate

Tool-Temp AG spoke with Mr Robin Auer, Head of Marketing at Chocolat Stella Bernrain, about the production of chocolate – from the grains of cocoa beans to the crucial temperature control of the chocolate, as well as about developments and innovations in chocolate production.

The Swiss manufacturer of premium chocolate, Chocolat Stella Bernrain, produces high-quality chocolate specialities for corporate customers around the world. Tool-Temp temperature control units are used to simplify the manufacturing process and help improve production quality. Founded in 1932 and based in Kreuzlingen and Giubiasco, Switzerland, Chocolat Stella Bernrain is committed to sustainability in both the sourcing of raw materials and production, and is dedicated to genuine Swiss quality in its chocolate specialties.

1. How has Chocolat Stella Bernrain developed over the more than 90 years of its existence?

Chocolat Bernrain AG was founded in 1932 as a manufacturing company and progressively expanded into an industrial production company. In 1980, Chocolat Stella SA, located in Giubiasco, was taken over by Chocolat Bernrain AG. Since then, the two companies have been working together under the name Chocolat Stella Bernrain. The third-generation family member, Monica Müller, has been leading the company since 2007. Under her leadership, the new factory in Giubiasco was built in 2013 and an enlargement in Kreuzlingen followed in 2021, thereby doubling the previous production area. Today, the company counts around approximately 200 employees in both locations.

2. How has your product range changed over time, and what innovative chocolate products do you offer today?

Starting with just a few chocolate products, the company has expanded its range over the years. During this time, Stella Bernrain has proven its innovative strength once again. In 1991, the company committed itself to sustainable production and launched the first organic and Fairtrade certified chocolates. In the last few years, a range of vegan chocolates has been launched and continues to be sold successfully. Today, sustainable packaging solutions are increasingly in demand. This is why Chocolat Bernrain offers compostable films. The company also aims to reduce the amount of packaging material by using single-layer packaging for products that are traditionally packaged in two layers. The used paper-based packaging material offers the same essential sealing properties as conventional products.

3. Why is maintenance of the optimum chocolate temperature crucial for the end product?

The maintenance of the optimum temperature is essential in the production of chocolate. The right temperature influences the texture, shine and flavor of the finished product. Precise temperature control ensures the perfect consistency and shine of the chocolate. Moreover, the right temperature allows the chocolate to develop its full flavor, ensuring a delicious taste. In short, temperature control is crucial for producing the best possible chocolate which everyone wants to enjoy.

4. What role do Tool-Temp temperature control units play in your daily process or product quality requirements?

We use the temperature control unit to heat some of our conches and to melt blocks of cocoa mass. The precise temperature control as explained above is very important to ensure the high quality of our products.

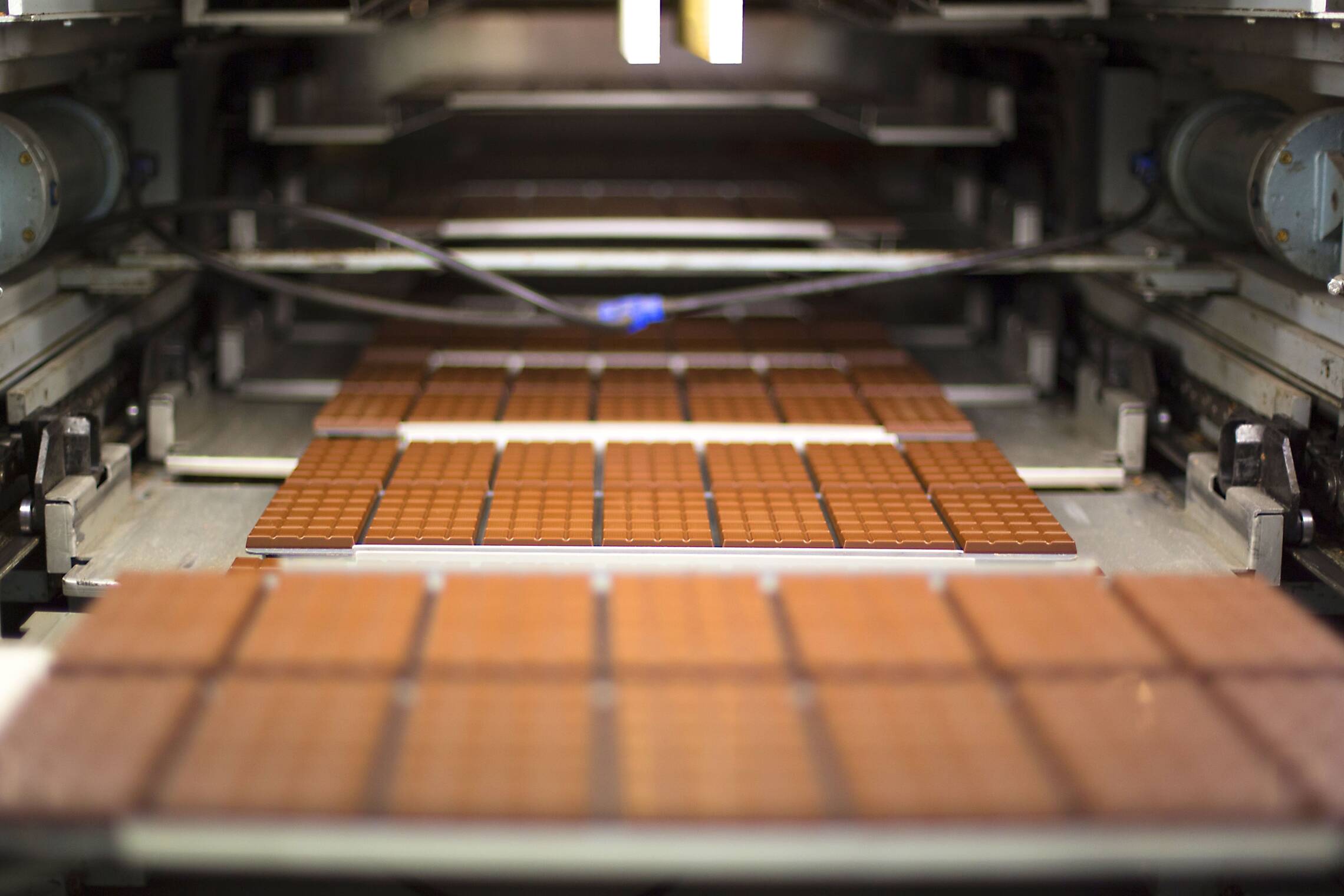

Production of chocolate bars at Chocolat Bernrain AG.

Chocolate production at Chocolat Bernrain AG.

5. How long does it take approximately take from the cocoa harvest until the finished chocolate arrives to a consumer?

It can take almost a year from the time the cocoa is harvested to the time the chocolate reaches the customer. Harvesting usually takes place twice a year. After the harvest, it can take several weeks to months for the cocoa to reach the factory for processing, depending on transport options and demand. The actual chocolate production takes between 24 and 72 hours, depending on how long the chocolate is being conched. The final moulding process into bars or pralines takes a very short time as we can mould over 1,500 kg of chocolate per hour into bars.

6. How many hours per day are the Tool-Temp temperature control units in operation?

The conching devices operate around the clock. The temperature control unit for the melter automatically switches off when the job is finished. This was very easy to implement as the units have remote start/stop.

7. Is there anything else you would like to add about your experience with Tool-Temp temperature control units?

“We are very happy with the temperature control units. The customer service is excellent and we receive very detailed information when any questions arise. In the event of a repair, a technician is quickly on site,” says Mr. Roger Näf, Head of Technology, about the use of Tool-Temp temperature control units in their production.